The Cost of Failure: Beyond the Component Price

In industrial maintenance, the cost of a failed tubular heater is rarely the $50 replacement part. It is the $5,000 per hour in downtime, the wasted batch of raw materials, and the disruption to the production schedule.

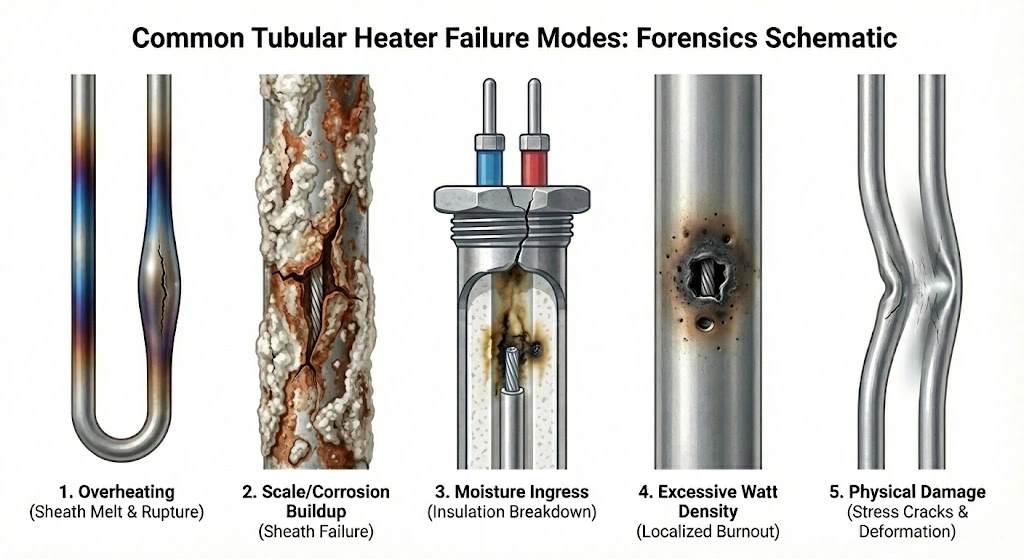

Most heater failures are dismissed as “wear and tear.” However, forensic analysis reveals that over 80% of failures are not manufacturing defects, but symptoms of “Misapplication”—a mismatch between the heater’s design parameters and the operational reality.

Drawing from ASTM standards and Hongtai’s manufacturing data, this guide applies a Root Cause Failure Analysis (RCFA) approach to the five most common failure modes. We don’t just tell you what broke; we analyze why it broke, so you can engineer the problem out of existence.

Scale buildup causing tubular heater failure / Corroded heater sheath example

Mode 1: Overheating & Meltdown (The “Heart Attack”)

The Symptom: The heater sheath is bulged, split open, or physically melted. The internal resistance wire is fused.

Root Cause A: Excessive Watt Density

Thermodynamics dictates that heat generated must be dissipated. If the Watt Density (W/in²) exceeds the medium’s ability to carry heat away, the internal temperature skyrockets.

- The Physics: Even utilizing high purity magnesium oxide (MgO) powder compacted for maximum heat conductivity1, there is a physical limit. If the core temperature exceeds the melting point of the precision helical wound nickel-chrome resistance wire2, the element will self-destruct.

- Forensic Sign: A longitudinal split along the sheath often indicates the internal wire vaporized, creating intense pressure.

Root Cause B: Sheath Material Temperature Limits

If a heater looks blackened or oxidized (scaling) shortly after installation, the sheath material likely exceeded its metallurgical limit.

- The Limit Check:

- Steel is rated for 400°C (Oil)3.

- SS304 is rated for 650°C4.

- Forensic Verdict: If the application required 750°C surface temp, using SS304 inevitably leads to oxidation failure. The correct specification was Incoloy 8005.

Mode 2: Corrosion & Rupture (The “Chemical Attack”)

The Symptom: Small pinholes appear on the sheath surface. The heater trips the breaker due to low insulation resistance (fluid ingress).

Root Cause A: Pitting Corrosion

This is common in chloride-rich environments (e.g., treated tap water).

- The Mismatch: Using Copper (rated only for water/non-corrosive liquids 6) in an acidic bath will result in rapid dissolution. Even SS304 can suffer pitting in saline.

- Prevention: Upgrade to SS316 for corrosive liquids 7 or Incoloy 800 for severe environments.

Root Cause B: The Scale Effect

In hard water or heavy oil, mineral/carbon deposits form on the sheath.

- The Chain Reaction: Scale is a thermal insulator. It traps heat inside the tube. A heater designed for water (High Watt Density) will behave like it is running in dry air if covered in scale, leading to rapid overheating and sheath rupture.

Mode 3: Cold Pin & Terminal Failure (The “Hot Spot”)

The Symptom: The heating element is fine, but the electrical terminal or lead wire has melted or arced.

Root Cause: Insufficient Cold Zone

Heat is generated by the resistance wire, but power is delivered via a “Cold Pin.”

- The Mechanism: The integral cold pin is fusion welded to the resistance wire 8 to create a non-heating zone near the terminal.

- The Failure: If this Cold Zone is too short for the mounting depth (e.g., passing through thick insulation), the heat generation point sits inside the wall or too close to the terminal box.

- Prevention: Verify the “Unheated Length” in your specs. Additionally, ensure threaded screw terminals with ceramic or mica insulators 9 are used to withstand residual heat.

Mode 4: Dielectric Breakdown (The “Short Circuit”)

The Symptom: The heater trips the GFCI/breaker immediately upon startup. Visually, the heater looks new.

Root Cause: Hygroscopicity (Moisture Ingress)

High purity magnesium oxide is an excellent electrical insulator10, but it is highly hygroscopic (absorbs moisture from air).

- The Scenario: If a heater sits in storage for months in a humid warehouse, or if the sealing epoxy cracks, moisture enters the MgO. Water conducts electricity, causing a short circuit between the wire and the sheath.

- Forensic Tool: A Megohmmeter (Megger) test showing < 1 MΩ indicates moisture.

- The Fix: “Bake out” the heater in an oven at 120°C for several hours to drive out moisture before powering up.

Mode 5: Mechanical Fit & Tolerance Issues

The Symptom: Premature failure in conductive heating (insertion heaters) where the heater is inserted into a metal mold.

Root Cause: Poor Fitment (Air Gaps)

In conductive heating, air is the enemy.

- The Tolerance: We manufacture to a strict Sheath Diameter tolerance of ±0.15mm11.

- The Failure: If the drilled hole is too large, an air gap acts as an insulator, forcing the heater to run hundreds of degrees hotter than the mold.

- Prevention: Use thermal transfer paste and ensure a tight fit (H7 tolerance hole).

Engineer’s Self-Check: Prevention Checklist

Before ordering a replacement, run this diagnostic checklist to prevent history from repeating.

- Check Voltage: Did you wire a 240V heater into a 480V line? (Doubling voltage quadruples wattage!). Max voltage capability is 550V12.

- Check Resistance: Measure ohms ($\Omega$). Is it within +10% / -5% of the spec?13.

- Check Sheath: Is the material compatible? (e.g., Copper for 150°C, Incoloy for 800°C 14).

- Check Connections: Are the ceramic/mica insulators cracked?15.

Troubleshooting Visuals & Diagnostics

Interactive Diagnostics Flowchart

- Heater not hot? $\rightarrow$ Check Resistance $\rightarrow$ Infinite $\Omega$? $\rightarrow$ Open Circuit (Broken Wire).

- Breaker Trips? $\rightarrow$ Check Insulation (Megger) $\rightarrow$ Low $\Omega$? $\rightarrow$ Moisture Ingress.

- Sheath Split? $\rightarrow$ Check Watt Density $\rightarrow$ Too High? $\rightarrow$ Overheating.

Watt Density “Rule of Thumb”

- Water: 10 W/cm² (60 W/in²)

- Oil: 2-3 W/cm² (15-20 W/in²)

- Air: 5 W/cm² (30 W/in²)

Frequently Asked Questions (FAQ)

Q: Why did my tubular heater split open shortly after use?

A “split sheath” is a catastrophic failure caused by internal pressure, typically stemming from two root causes:

- Excessive Watt Density: The heat could not escape fast enough into the medium, causing the internal temperature to exceed the limits of the MgO insulation and the metal sheath.

- Moisture Ingress: If the seal failed or the heater was stored improperly, the internal MgO powder absorbed moisture. Upon rapid heating, this trapped water turned to steam instantly, creating immense pressure that ruptured the metal tube from the inside.

Q: How do I tell if a heater is Open or Shorted?

You can diagnose this using a standard multimeter to measure resistance (Ohms):

- Open Circuit (Broken Wire): The meter reads “Infinite” or “OL” (Over Limit). This usually means the internal helical resistance wire has melted through or broken, often due to overheating or vibration.

- Short Circuit: The meter reads zero or very low resistance to the ground (the outer metal sheath). This indicates that the internal insulation has failed, or the sheath has been punctured, allowing electricity to leak to the casing.

Q: My oil heater has heavy black carbon buildup. Is this normal?

No, heavy coking (carbon buildup) indicates that the Surface Load (Watt Density) is too high for the oil you are heating. Oil conducts heat much more poorly than water. If you use a high-wattage heater designed for water, the oil will burn onto the sheath surface. For oil applications, we strictly recommend using Steel sheaths with a low watt density (approximately 2-3 W/cm²). Continued operation with heavy scale acts as insulation, which will eventually cause the heater to overheat and fail.

Need High-Temperature Resistance? Need Cost-Effective Solution?

Want to know how to select it? Our latest selection guide can help you.