The Conductivity Challenge: Why Air is Difficult to Heat

For thermal engineers, air is a notoriously difficult medium. Its thermal conductivity is approximately $0.026 W/m\cdot K$—roughly 20 times lower than stationary water.

If you place a standard “bare” tubular heater in an air stream, the heat cannot escape the sheath fast enough. The result? The surface temperature spikes dangerously high while the air remains lukewarm.

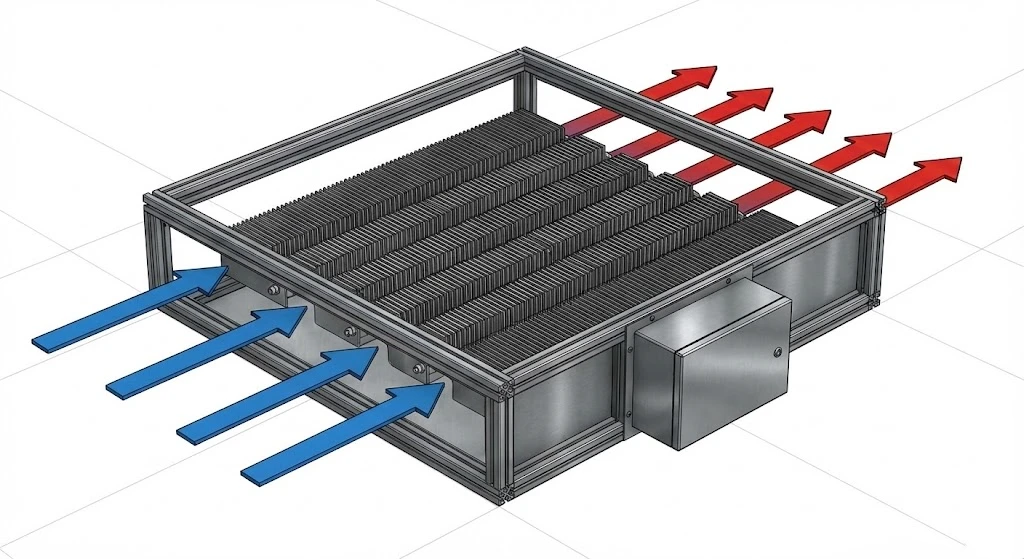

The Solution: Finned Tubular Heaters. By spiral-winding a continuous metal fin around the sheath, we increase the surface area by 400% to 500%. This reduces the surface watt density, allowing the element to “trick” the air’s low conductivity and transfer heat efficiently.

At Hongtai, we engineer both standard tubular elements and specialized high temperature process air heaters 1 designed to conquer these thermodynamic challenges.

1. To Fin or Not to Fin? The Engineering Decision

Fins are not a universal solution. They introduce aerodynamic resistance. Use this boundary analysis to determine if fins are right for your system.

Static Air vs. Forced Circulation

- Static Air (Natural Convection): In applications without fans, dense fins can actually block the natural rise of hot air, creating localized “heat islands.” For static air, low-watt-density bare elements are often superior.

- Forced Air: Fins are the dominant choice here. The moving air scrubs the heat from the fins. However, the velocity must be sufficient to penetrate the space between fins.

The Contamination Trap

- Clean Air: Fins are ideal.

- Dirty Air (Fibrous/Oil Mist): In textile dryers or oily environments, fins act as a filter, trapping debris. This buildup insulates the heater, causing carbonization and fire. In these scenarios, use unfinned Incoloy 800 elements, which are self-cleaning at high temperatures.

2. Material Matching: From 200°C to 800°C

Selecting the right alloy is critical for preventing oxidation scale, which ruins heat transfer. We manufacture based on the following ASTM-compliant temperature thresholds:

Low-to-Mid Temperature (< 400°C)

For standard drying ovens and HVAC duct heaters where moisture is low:

- Sheath: Steel.

- Limit: According to our material specifications, Steel is rated for a maximum of 400°C2.

- Advantage: This is the most economic solution for non-corrosive air heating.

High Temperature Process Air (> 600°C)

For annealing ovens, load banks, or high-velocity process heat:

- Sheath: Incoloy 800.

- Limit: Incoloy 800 maintains structural integrity and resists oxidation up to 800°C3.

- Critical Detail: When specifying Incoloy elements, ensure the fins are also stainless steel or high-nickel alloy. Using carbon steel fins on an Incoloy tube will result in the fins scaling and detaching at high temperatures, leaving the tube bare.

3. Aerodynamics: Pressure Drop & Velocity

As a system integrator, you are not just buying a heater; you are managing a fan curve. Adding fins increases the Pressure Drop ($\Delta P$) across the duct.

Minimum Velocity Requirements

To effectively strip heat from the fins and prevent sheath overheating, a minimum face velocity of 2-3 m/s (400-600 fpm) is recommended.

- Risk: Below this velocity, the airflow becomes laminar, bypassing the space between fins.

The Pressure Drop Trap

If you retrofit a finned heater into an existing duct without checking the fan’s Static Pressure, the added resistance may reduce the total airflow (CFM).

- Result: Reduced CFM = Lower Heat Transfer Coefficient = Heater Overheating.

- Design Tip: If pressure drop is a concern, request a lower “Fin Pitch” (fewer fins per inch) from our engineering team to open up the airway.

4. Installation & Layout: Preventing “Thermal Short Circuits”

Staggered vs. In-Line Arrays

When installing multiple heating elements in a bank:

- Avoid In-Line: Placing tubes directly behind one another means the rear tubes sit in the hot “shadow” of the front tubes, reducing efficiency.

- Choose Staggered: Offset the rows. This forces the airflow to change direction, creating turbulence. Turbulence breaks the boundary layer on the fins, significantly increasing the heat transfer rate.

Managing the Cold Zone

Your duct wall insulation is likely 50-100mm thick.

- The Hazard: If the heating coil starts inside the insulation, it will burn out.

- The Fix: We utilize an integral cold pin fusion welded to the resistance wire4. You must specify a Cold Zone length that exceeds your insulation thickness. This ensures the threaded screw terminals 5 remain in the cool ambient air outside the duct, protecting the wiring.

Technical Rule of Thumb: Velocity vs. Watt Density

Use these guidelines to estimate the safe maximum Watt Density for your air heater. Note: Always verify with Hongtai engineering.

| Air Condition | Velocity (m/s) | Max Watt Density (W/cm2) | Recommended Material |

| Static Air | 0 | 2 – 4 | Steel / SS304 |

| Low Velocity | 3 | 5 – 6 | Steel / Incoloy |

| High Velocity | 6+ | 8 – 12 | Incoloy 800 |

Reminder: Even with high airflow, never exceed the sheath temperature limit of 800°C for Incoloy 800 6or 400°C for Steel7.

Frequently Asked Questions (FAQ)

Q: When should I choose a Finned Heater over a standard Tubular Heater?

Choose finned heaters when you are heating gases (air, nitrogen) and have forced circulation (a fan). The fins increase surface area, allowing you to put more power into a smaller space. However, if you are heating liquids (water, oil) or air with heavy dust/sticky contaminants, you must use standard bare tubular heaters to prevent fouling.

Q: Which sheath material is best for an air duct heater?

It depends on the operating temperature. For standard drying and HVAC applications below 400°C, Steel is the most cost-effective and standard choice. For high-temperature process air, annealing, or heat treating above 400°C (up to 800°C), you must use Incoloy 800 to prevent oxidation and scale buildup.

Q: How does airflow velocity affect heater design?

Velocity is crucial. Higher velocity (air speed) strips heat away faster, allowing for a higher Watt Density (more power). If velocity is low (< 2 m/s), you must reduce the heater’s wattage to prevent the sheath from overheating. Always check that your fan can handle the pressure drop introduced by the fins.

Need a Thermal Simulation?

Balancing pressure drop and heat transfer is complex. Send us your duct dimensions and CFM requirements. Hongtai Engineering can help you design the optimal fin pitch and element layout.