Introduction

A high-density cartridge heater without a control system is not a tool; it is a fuse waiting to blow.

In high-watt density applications, the internal temperature of a heater can rise at a rate of 50°C per second. If you rely on a manual switch or a slow-reacting external sensor, the heater core will melt before the heat even reaches the mold surface. This phenomenon, known as Overshoot, is the primary cause of premature element failure.

To build a reliable thermal system, you need more than just a heating element. You need a “Nervous System” (The Thermocouple) and a “Brain” (The PID Controller).

This guide bridges the gap between the heater and the control panel. We will deconstruct the engineering choice between Type J and Type K thermocouples, explain why Grounded Junctions can crash your controller, and provide the wiring logic for Solid State Relays (SSR) that ensures $\pm 1^\circ C$ precision.

Note: Before designing your control loop, ensure the heater itself is sized correctly. Review our [Watt Density Calculation Field Guide]. And [2026 Cartridge Heater Uitimate Guide: From SelectionLogic to Failure Analysis]

A schematic diagram of a Closed-Loop System: 1. Cartridge Heater (Plant), 2. Internal Thermocouple (Sensor), 3. PID Controller (Controller), 4. Solid State Relay (Actuator). Arrows show the signal flow.

1. Built-in Thermocouples: Giving the Heater a “Nervous System”

Many engineers search for “Cartridge Heater with Thermocouple” because they have limited space. Integrating the sensor inside the heater allows for a compact, single-probe solution.

J-Type vs. K-Type: The Industrial Standards

These two sensor types account for 90% of industrial applications. Choosing the wrong one leads to measurement errors or premature oxidation.

| Feature | Type J (Iron / Constantan) | Type K (Chromel / Alumel) |

| Color Code (ANSI) | Black (+), Red (-) | Yellow (+), Red (-) |

| Temp Range | 0°C to 750°C | 0°C to 1250°C |

| Atmosphere | Reducing (Vacuum/Plastics) | Oxidizing (Clean Air) |

| Sensitivity | High ($50-55 \mu V/^\circ C$) | Medium ($41 \mu V/^\circ C$) |

| Best Use | Injection Molding (Plastics) | General Purpose / High Temp |

Engineering Verdict: If you are molding plastics below 500°C, Type J offers slightly better resolution and is the standard for legacy injection machines. For temperatures above 600°C or general use, Type K is safer due to its oxidation resistance.

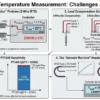

The Junction: Grounded vs. Ungrounded

This is the most common specification error. The “Junction” is where the two thermocouple wires meet.

- Grounded (Fast): The junction is welded directly to the heater sheath.

- Pros: Instant thermal response.

- Cons: Electrical Noise. Since the sheath is conductive, electrical interference (EMI) from the heater coil can travel up the sensor wire and scramble the PID controller.

- Ungrounded (Clean): The junction floats in the MgO insulation, isolated from the sheath.

- Pros: Clean, noise-free signal. Safer for sensitive electronics.

- Cons: Slight thermal lag (1-3 seconds).

Recommendation: For modern digital PID controllers, always specify Ungrounded to prevent “Ground Loops” and erratic readings.

[Visual Element]: A cross-section diagram showing the internal tip of a heater. Left: “Grounded” (Wires touch the metal tip). Right: “Ungrounded” (Wires suspended in MgO powder).

2. The Controller: The “Brain” Behind the Heat

Connecting a high-performance heater to a simple ON/OFF switch is like driving a Ferrari with a brick on the gas pedal.

PID vs. ON/OFF Control

- ON/OFF Control: The heater runs at 100% power until it hits the setpoint, then cuts to 0%.

- Result: The thermal inertia causes the temperature to fly past the target (Overshoot), then drop way below it (Undershoot). This thermal cycling fatigues the heater wire.

- PID (Proportional-Integral-Derivative): The controller pulses the power. As the temperature nears the target, it slows down (e.g., pulsing on for 0.1 seconds every second).

- Result: Smooth, flat-line temperature control ($\pm 1^\circ C$) and significantly longer heater life.

The Solid State Relay (SSR) Necessity

PID controllers switch power on and off rapidly (often once per second).

- Mechanical Contactors: Will wear out physically within weeks due to arcing and mechanical fatigue.

- Solid State Relays (SSR): Have no moving parts. They can switch millions of times without wear.Rule: If using PID, you must use an SSR.

3. Mastering Thermal Lag: Installation & Physics

Even the best controller cannot break the laws of physics. Heat takes time to travel from the coil to the sensor.

Junction Location Strategy

Where we place the thermocouple inside the heater matters.

- Bottom (Tip) Sensing: Best for monitoring the mold temperature, as the tip is in contact with the bore.

- Middle Sensing: Best for monitoring the heater average temperature.

- Center vs. End: If your heater has Distributed Wattage (hotter ends), placing the sensor in the center might give a “safe” reading while the ends are burning out.

Soft Start (Bake Out) Function

Modern controllers (like Watlow or Omron) feature a “Soft Start” mode.

- The Logic: When a heater is cold, the MgO might have absorbed moisture. If you hit it with 100% power, the moisture turns to steam and bursts the heater.

- The Function: The controller limits voltage to 50% for the first 5 minutes to gently evaporate moisture before going to full power.

[Visual Element]: A line graph comparing “ON/OFF Control” (Sine wave oscillation) vs. “PID Control” (Flat line approaching setpoint).

4. Troubleshooting: Why is my Temperature Jumping?

If your controller display is showing random numbers or error codes, check these three culprits.

1. Polarity Reversal (The “Negative” Heat)

- Symptom: As the heater gets hotter, the temperature reading goes down or shows a negative value.

- Cause: You swapped the Red and White/Yellow/Black wires. Thermocouples are DC devices; polarity matters.

2. EMI / RFI Noise (The “Jumping” Digits)

- Symptom: The temp reads 200°C, then jumps to 250°C, then back to 201°C in split seconds.

- Cause: You are using a Grounded thermocouple or unshielded extension wire running next to high-voltage power lines.

- Fix: Switch to an Ungrounded thermocouple or use Shielded Twisted Pair extension wire.

3. Open Loop (Display: “Err” or “9999”)

- Symptom: Controller shows maximum value or error.

- Cause: The thermocouple wire is broken. Check the connection at the lead exit—this is the most common flex-point breakage.

5. Zero-Click Checklist: Ordering an Integrated System

When sourcing a “Smart Heater” from ht-heater.com, define the full loop:

- [ ] Sensor Type: J or K?

- [ ] Junction: Grounded (Fast) or Ungrounded (Noise-Free)?

- [ ] Location: Tip or Middle?

- [ ] Voltage: 120V/240V for Heater? 12-24V DC for Controller Output?

- [ ] Lead Length: Do you need the sensor leads to be longer than the power leads?

FAQ: Control & Integration

Can I use a built-in thermocouple to control the mold temperature?

You can, but it is not ideal. An internal sensor measures the heater’s internal temp, which is always hotter than the mold.

Better Approach: Use the internal sensor as a High Limit Safety (to protect the heater) and mount a separate external thermocouple in the mold steel to control the process.

My controller is an Omron E5CC. Is your heater compatible?

Yes. Our internal thermocouples adhere to standard ANSI/IEC calibration curves. They are compatible with any universal input controller (Omron, Watlow, RKC, Honeywell, etc.).

Why does my heater overshoot the setpoint by 20 degrees on startup?

This is a PID tuning issue, not a heater issue. Your “Auto-Tune” might need to be re-run. The controller needs to “learn” the thermal mass of your mold to know when to back off the power before hitting the target.