Introduction & The Thermal Window

In the relentless, high-speed world of Stretch Blow Molding (SBM), the thermal processing window is brutally narrow. When transforming a rigid plastic preform into a crystal-clear beverage bottle at a rate of 40,000 bottles per hour, the preform temperature must be precisely controlled between 90°C and 110°C.

If the temperature deviates by even a few degrees, or if the heat distribution is uneven across the wall thickness, the results are immediate and costly: off-center bases, uneven wall distribution, blown-out sides, or a hazy, pearlescent finish. In PET manufacturing, heating is not simply a matter of getting the plastic hot; it is a complex 3D chess game of thermodynamic profiling.

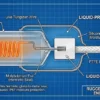

The secret to winning this game lies entirely in the Depth of Penetration. A standard industrial heater will only scorch the outer skin of the preform. A precision PET blow molding heater—specifically a customized short-wave halogen lamp—is engineered to penetrate through the 4mm thick plastic wall, achieving true volumetric heating before the preform enters the blowing mold.

Engineering Context: Different plastics require entirely different wavelengths for optimal curing. To understand why PET specifically demands short-wave radiation while other plastics (like PVC or ABS) use medium-wave, review our core Industrial Quartz Heating Tubes: The Complete Engineering Guide before attempting to diagnose your oven’s thermal profile.

PET Physics: Why Short-Wave Halogen is Mandatory

Why do SBM machine manufacturers (like Sidel, Krones, or KHS) exclusively utilize Tungsten Halogen lamps rather than longer-lasting carbon fiber heaters? The answer lies in the atomic absorption properties of Polyethylene Terephthalate (PET).

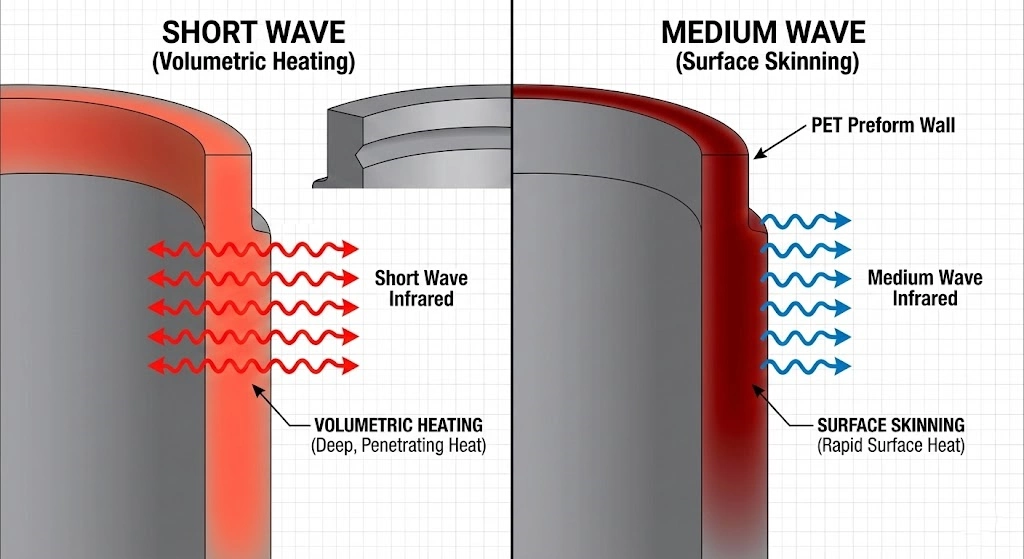

1. Surface Heating vs. Volumetric Heating

If you attempt to heat a thick PET preform using a medium-wave infrared emitter (peaking around 2.5μm), the energy will be completely absorbed within the first 0.5mm of the plastic’s surface.

- The Failure Mode: The outer wall of the preform rapidly overheats, softens, and begins to crystallize (turning white), while the inner wall remains cold, hard, and unyielding. When the stretch rod extends, the cold inner core tears or stretches unevenly.

2. The 1.0μm Short-Wave Penetration Advantage

A specialized halogen PET blow molding heater operates at a brilliant color temperature of 2400K to 2500K, generating high-energy photons with a peak wavelength between 0.8 and 1.2μm. PET plastic is semi-transparent to this specific short-wave bandwidth. When the preform rotates continuously through the heating tunnel, the short-wave radiation physically passes through the outer wall and travels deep into the inner wall. This creates Volumetric Heating, ensuring the temperature differential (ΔT) between the outside skin and the inside core of the preform is nearly zero.

Zone Control: Designing the Perfect Thermal Profile

Blowing a complex bottle (especially one with a petaloid base for carbonated drinks) requires vastly different amounts of heat at different vertical heights along the preform. SBM ovens achieve this via a highly controlled Vertical Heating Array.

1. Neck Protection (The Cold Zone)

The threaded neck of the preform must never exceed its glass transition temperature, or the cap will not seal, causing the bottle to leak carbonation or fluid. The uppermost PET blow molding heaters are precision-aligned with water-cooled aluminum shielding rails. This creates a razor-sharp thermal cutoff line, blasting the body of the preform with intense short-wave heat while keeping the threaded neck completely cold and dimensionally stable.

2. The Vertical Heating Matrix

Inside the oven, 6 to 10 halogen lamps are stacked horizontally, forming a vertical “heating wall.” Each lamp zone operates at a different power level.

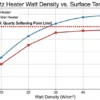

- The Base (High Power): The injection-molded gate at the bottom of the preform is the thickest part of the plastic. The bottom-most heater must often run at 100% output (e.g., 2000W) to ensure the base is soft enough to stretch into the complex corners of the mold.

- The Body (Modulated Power): The middle zones are typically modulated down to 50% or 60% power to prevent the thinner body walls from over-stretching and blowing out.

Reflective Coatings: Focusing the Beam at High Speeds

Preforms travel through an SBM oven at staggering speeds, often spinning past the lamps in just a few seconds. A standard, clear 360° halogen lamp wastes 50% of its radiant energy heating the steel back-plate of the oven.

1. Ceramic White Reflector (Coated White Processing)

To maximize energy transfer to the spinning preform, the industry standard is to apply a Half-Coated White Ceramic Reflector directly to the rear of the quartz tube.

Why ceramic white instead of a highly polished gold reflector? SBM ovens are incredibly violent environments. The heavy mechanical stamping of the molds transmits high-frequency vibrations throughout the chassis, and ambient temperatures are intense. A gold coating can degrade or peel under these extreme continuous conditions. A proprietary ceramic white glaze, however, is sintered directly into the quartz glass. It easily withstands 800°C ambient temperatures, will never peel, and permanently focuses 180° of the intense short-wave radiation directly onto the passing preform, increasing process efficiency by up to 30%.

Troubleshooting: Reading the Bottle’s “Thermal Medical Chart”

For maintenance managers and MRO technicians, the blown bottle tells the exact story of what is failing inside the infrared oven. Here are the primary diagnostic rules:

Symptom A: Pearlescence (Haziness or Cloudy White Walls)

- Diagnosis: “Cold Stretching.” The PET was stretched before it reached the optimal 90°C+ state. The microscopic molecular chains were physically torn rather than stretched, causing micro-voids that scatter light (making it look cloudy).

- The Fix: You lack penetration. Check the oven to see if a specific halogen tube has burned out, or increase the power percentage on the heating zones corresponding to the hazy height on the bottle.

Symptom B: Localized Crystallization (Solid White Patches)

- Diagnosis: Overheating. The PET temperature exceeded 115°C, causing the amorphous plastic to transition into a hard, crystalline state.

- The Fix: The preform absorbed too much surface energy. Decrease the watt density of the lamp at that specific zone height, or increase the rotational speed of the preforms through the oven.

Symptom C: Off-Center Base (The Gate is Crooked)

- Diagnosis: Uneven pre-heating at the bottom of the preform.

- The Fix: The thickest part of the plastic did not soften uniformly. Check the bottom-most, highest-power halogen tube in the array. As halogen lamps age past 5000 hours, their output can degrade. It is likely time for a replacement.

OEM Replacement Capability: Stop Paying Brand Markups

When a lamp fails on a Sidel, Krones, SIG, or KHS machine, procurement managers often panic and order replacement parts directly from the European OEM at a massive premium, fearing that aftermarket lamps will compromise their 40,000-bottle-per-hour line.

This is an unnecessary engineering tax.

1. Exact 1:1 Reverse Engineering

Hongtai specializes in manufacturing direct, drop-in replacement PET blow molding heaters. If you provide the Total Length, Heated Length, Voltage (e.g., 240V or 400V), and Wattage, we replicate the exact thermophysical performance of the original European lamp. We match the spectral output, the color temperature (2400K-2500K), and the specific ceramic end-caps (such as SK15 or custom wire leads) to ensure seamless integration into your machine’s PLC control loops.

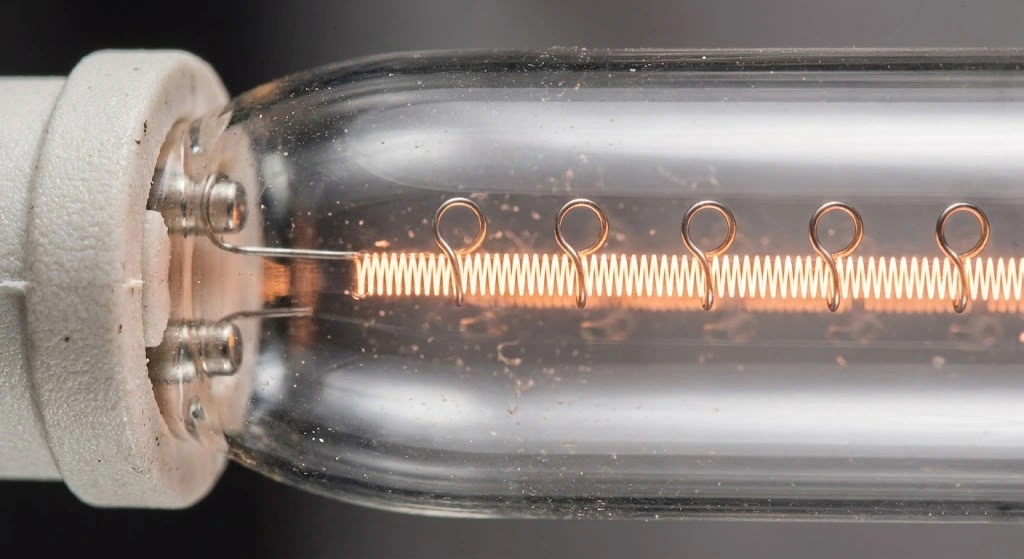

2. Extreme Vibration Resistance

Standard commercial halogen lamps will shatter within hours inside an SBM machine due to the violent pneumatic vibrations of the mold clamps. Hongtai’s PET replacement lamps are constructed with a specialized Molybdenum Wire Support System. We insert tiny, high-temperature molybdenum rings throughout the length of the quartz tube. These rings grip the delicate tungsten filament, preventing it from sagging, vibrating, or short-circuiting against the glass wall. This guarantees the lamp achieves its full 5,000 Hour operational lifespan even in the most brutal high-speed environments.

FAQ: SBM Heater Maintenance

How often should I replace the infrared lamps in my blow molding machine?

Assuming your machine uses a soft-start SCR controller and your facility has stable voltage, our halogen lamps are rated for 5,000 hours of continuous use. However, we highly recommend a Group Replacement strategy. Do not replace lamps one by one as they fail. Replacing the entire oven array at 4,500 hours ensures the thermal degradation curve remains identical across all zones, preventing endless daily adjustments to your PLC heating profile.

Why do the ends of my heating lamps turn black after a few months?

This indicates a failure of the Halogen Cycle. It usually occurs because the ceramic end-caps (the cold ends) are operating at too low of a temperature, or the machine’s cooling fans are blowing too aggressively on the ends of the tubes. When the ends are too cold, the evaporated tungsten cannot combine with the halogen gas, and it deposits as a black metallic soot on the glass, prematurely ending the lamp’s life.

Can I replace a clear lamp with a white-coated lamp in my current machine?

Yes, and it is highly recommended. By switching to a ceramic white-coated tube, you will significantly increase the forward-directed radiant heat hitting the preform. You will likely need to adjust your machine’s PID parameters downward to compensate for the increased efficiency, ultimately resulting in a 15% to 20% reduction in your oven’s electrical consumption.

Conclusion: Stop Paying OEM Markups

A perfect PET bottle is born from a perfect spectrum. In high-speed stretch blow molding, the heating array is not merely a collection of consumable lightbulbs; it is the core precision instrument that dictates your Overall Equipment Effectiveness (OEE) and your scrap rate.

Stop paying OEM markups for replacement lamps. Do not let long lead times from European manufacturers dictate your production schedule. Take a photograph of your burned-out lamp, note the machine brand, and send the specifications to the Hongtai Thermal Engineering Department. Within 24 hours, our engineers will provide a spec-for-spec cross-reference sheet and a prototype quotation, delivering identical performance at a fraction of the cost.

[Send Us Your OEM Lamp Specs for a Direct Replacement Quote]