Introduction & The Convection Flaw

In a traditional gas-fired convection oven, properly curing the powder coating on an automotive bumper or an alloy wheel can easily consume 30 to 40 minutes. But time is only part of the problem.

The most severe flaw of convection heating lies in its fundamental mechanism: Forced Airflow. To maintain temperature uniformity, giant industrial blowers must violently circulate hot air throughout the chamber. This high-velocity air acts as a delivery system for airborne contaminants. Microscopic dust particles, lint from operator clothing, or previously settled overspray are continuously blown directly onto the wet, tacky surface of the fresh paint, resulting in devastating “seed defects” or dirt inclusions that require expensive manual buffing and rework.

The engineering solution is radiant thermal transfer using an industrial Paint Curing Heater. Infrared energy travels at the speed of light and requires zero air medium to transfer heat. Zero air velocity means zero dust circulation.

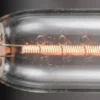

However, simply switching from gas to electric infrared is not enough; you must select the precise radiant wavelength for your specific polymers. Review our foundational Industrial Quartz Heating Tubes: The Complete Engineering Guide to understand why spectral matching is non-negotiable for high-gloss coating applications.

The Fatal Error: Why Short-Wave Halogen Ruins High-End Finishes

Many auto body shops or junior oven designers make the catastrophic error of purchasing off-the-shelf, high-intensity short-wave halogen lamps (operating at ~2400K) to accelerate their curing lines.

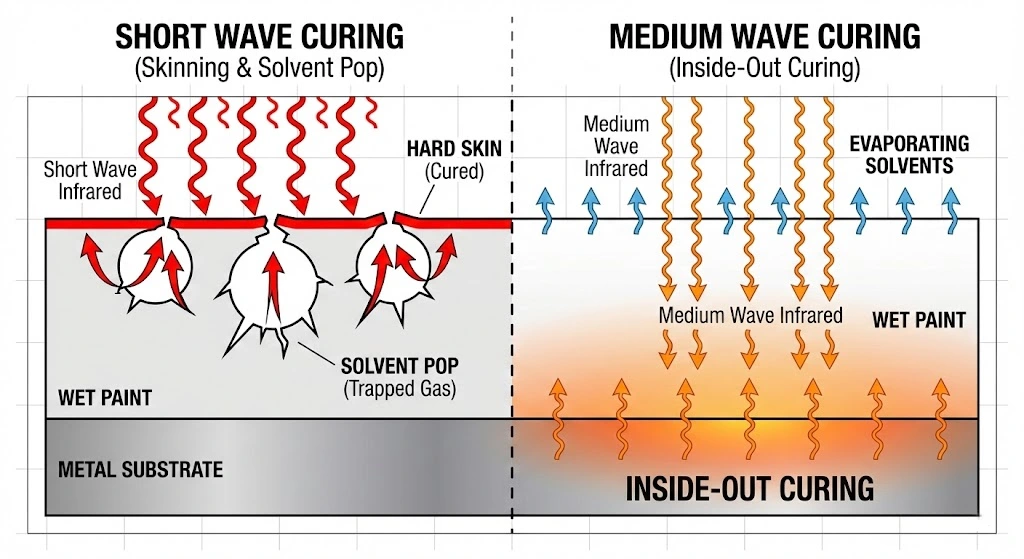

1. The Physics of Surface Skinning

Short-wave infrared radiation (peaking around 1.0μm) possesses massive photon energy and extreme penetrating power. When this intense radiation hits a layer of water-based paint, solvent-based clear coat, or electrostatic powder, it violently and instantly heats the very top molecular layer of the coating. This causes the surface to prematurely cure, harden, and form a sealed “skin.”

2. Solvent Pop (The Orange Peel Effect)

Once the surface is skinned over, the volatile organic compounds (VOCs) and water molecules trapped in the underlying layers of the paint have no escape route. As the heat continues to build, these trapped liquids eventually boil into gases. The pressurized gas forces its way upward, rupturing the hardened surface skin.

The result is a surface completely riddled with microscopic craters, pinholes, and blisters. In the automotive coating industry, this irreversible defect is known as “Solvent Pop” or the dreaded “Orange Peel” effect.

The Medium Wave Mastery: Carbon Fiber and Polymers

To achieve a flawless, mirror-like automotive finish, you must abandon short-wave transmission and embrace the physics of Absorption.

1. Spectral Resonance Overlap

Automotive clear coats, epoxy primers, and polyurethane powder coatings consist primarily of complex hydrocarbon chains (C-H bonds) and water molecules. Under infrared spectroscopy, these specific molecular bonds exhibit their most aggressive resonant absorption peaks between 2.0 μm and 3.5 μm.

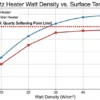

A specialized Carbon Fiber Paint Curing Heater operates at a lower color temperature (approximately 1200K). Consequently, its peak wavelength emission falls exactly within the 2.0 – 3.5 μm range. The radiant energy is perfectly overlapped with the material’s absorption profile.

2. Substrate Heating (Inside-Out Curing)

Because the medium-wave energy is perfectly tuned, it does not violently scorch the surface. Instead, a portion of the energy gently penetrates the wet coating layer and is absorbed by the underlying metal or plastic substrate.

The substrate becomes warm, and the thermal energy conducts upwards through the paint film. This drives the solvents and water to the surface before the top layer has a chance to cross-link and harden. This is true “Inside-Out Curing,” guaranteeing a glassy, defect-free finish.

Powder Coating Specifics: Melting & Cross-Linking

Powder coating presents its own unique set of thermodynamic challenges that carbon fiber emitters solve effortlessly.

1. Preventing Powder Blow-Off

Before it melts, powder coating is simply dry dust clinging to a grounded metal part via a fragile electrostatic charge. If you put this part into a high-velocity convection oven, the turbulent air will literally blow the powder off the edges and corners of the part (the Faraday cage areas), leading to uneven film thickness or cross-color contamination in the oven.

A carbon fiber paint curing heater operates in perfectly still air, preserving the delicate powder structure until it melts.

2. Rapid Gelling and Cross-Linking

To achieve maximum durability and chemical resistance, powder must rapidly transition through its “Gelling” phase into its final “Cross-linking” phase.

Using targeted medium-wave infrared, the powder absorbs energy so efficiently that the gelling phase can be reduced from 15 minutes (in a convection oven) down to a staggering 3 to 5 minutes.

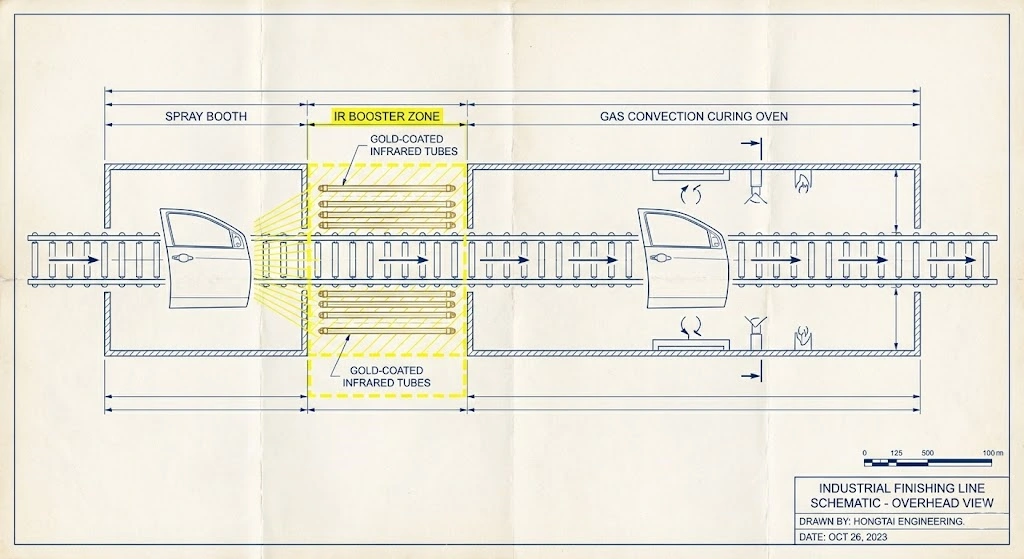

Retrofitting & Oven Design: The IR Booster Zone

For industrial plant managers and OEMs, adopting infrared technology does not require you to bulldoze your existing million-dollar gas convection ovens. The most cost-effective and highest-ROI upgrade is the integration of an IR Booster Zone.

1. The Pre-Heat / Flash-Off Tunnel

By bolting a compact, 2-to-3-meter-long infrared tunnel immediately after the spray booth and before the main convection oven, you create a “Flash-off Zone.”

As the freshly painted parts pass through this zone, high-density carbon fiber emitters rapidly drive out 70% to 80% of the water or solvents. When the part finally enters the turbulent convection oven, the paint is already “tacked up” or gelled, meaning dust can no longer stick to it. This simple addition can increase overall line speed by 30% to 40% without extending the physical footprint of the factory.

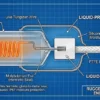

2. Directional Gold Reflectors

To maximize the efficiency of your IR Booster Zone, we engineer our quartz heating tubes with integrated Half-Gold or Ceramic White Reflectors. Rather than wasting 50% of your electrical energy heating the steel insulated walls of the oven tunnel, the reflectors force 100% of the radiant beam forward onto the automotive chassis.

Why the CFO Loves Infrared: Environmental & Energy ROI

While quality engineers love the flawless finish, financial directors approve infrared upgrades based on pure economics.

1. Massive Floor Space Reduction

Factory floor space is one of the most expensive overhead costs in manufacturing. A traditional gas convection tunnel required to cure powder coating at 5 meters per minute might need to be 30 meters long. By utilizing the intense, targeted absorption of a medium-wave paint curing heater array, that same line speed can often be achieved in an infrared tunnel just 10 meters long.

2. Zero Idle Energy (Sensor-Driven Heating)

A massive gas oven must be fired up an hour before the shift begins and remains burning gas all day, even if there are gaps in the production line.

Carbon fiber quartz emitters reach their peak operational temperature in 3 to 5 seconds. By pairing the heaters with optical conveyor sensors, the oven can instantly power down into a low-idle state when no parts are present, and instantly flash back to 100% power the moment a bumper enters the zone. This “On-Demand” heating radically slashes utility bills.

FAQ: Questions from Paint & Coating Engineers

Can I use halogen short wave for any paint curing applications?

Short-wave halogen is generally only appropriate for pre-heating thick, bare steel substrates before powder is applied, or for extremely rapid “spot repairs” in an auto body shop where the technician manually pulses the lamp to avoid overheating. For continuous, automated curing of wet paint or powder on a conveyor, medium-wave carbon fiber is the strict industry standard to prevent solvent pop.

How close should the infrared paint curing heater be to the painted surface?

This depends heavily on the engineered watt density of the tube and the absorption rate of the specific coating. Generally, an optimal distance is maintained between 150mm and 300mm. For highly complex, contoured automotive parts like bumpers, we highly recommend utilizing Custom 3D Bent Quartz Tubes (U-shape or Omega shape) to contour the heater to the part, ensuring the distance—and therefore the heat intensity—remains perfectly uniform across every curve.

Do infrared heaters work effectively on plastic parts like automotive bumpers?

Infrared is the ideal solution for plastics. Plastic polymers (like PP, ABS, or Polycarbonate) are thermal insulators; they conduct heat very poorly. A convection oven struggles to heat the plastic core without burning the surface. Medium-wave infrared energy is directly absorbed by the molecular structure of the plastic substrate, warming it evenly and safely without relying on thermal conduction.

Conclusion: Cure from the Inside Out

In the automotive finishing and powder coating industries, Surface Gloss and Adhesion are the ultimate metrics of value. A dusty, orange-peeled finish on a premium alloy wheel renders the entire manufacturing process worthless.

By upgrading from turbulent convection or harsh short-wave lamps to a precision Medium-Wave Paint Curing Heater, you are not simply speeding up your conveyor belt—you are fundamentally altering the thermodynamic curing profile of your polymers to eliminate defects at the molecular level.

Is your curing oven acting as the bottleneck in your production line?

Stop blowing dust onto your premium finishes. Send your conveyor speed, part dimensions, and coating MSDS (Material Safety Data Sheet) to the Hongtai Thermal Engineering Department. We will calculate the exact absorption parameters and engineer a custom carbon fiber infrared emitter array designed to cure your products flawlessly from the inside out.

[Consult Hongtai for a Custom Paint Curing Solution]