Introduction & The Medical Standard

In standard industrial manufacturing—such as plastic thermoforming or automotive paint curing—if a heating element sheds a microscopic flake of oxidized metal (scale) or experiences slight chemical outgassing, the worst-case scenario is a minor increase in the product rejection rate.

In medical engineering, however, heat is a prescription, not just a temperature. If a heating element inside an infant incubator, a blood analyzer, or a surgical fluid warmer releases particulates or outgasses toxic fumes into a sterile environment, it is not a manufacturing defect; it is a catastrophic biological hazard.

In the realm of life sciences and medical device manufacturing, the primary requirement for a thermal source is not merely “speed” or “power.” The absolute baseline requirement is Uncompromising Purity.

The definitive solution is the High-Purity Quartz Medical Infrared Heater. Because quartz glass (fused silica) is non-porous, chemically inert, and physically stable at extreme temperatures, it produces zero particulate shedding and zero outgassing. It is the only perfect infrared transmission medium for Class 100 cleanrooms and patient-critical medical equipment.

To ensure biological safety, you must precisely match the emitted energy spectrum to your specific biological application. Review our baseline Industrial Quartz Heating Tubes: The Complete Engineering Guide to understand the physics of wavelength selection before designing your medical chassis.

Cleanroom Compatibility: The Sterile Advantage of High-Purity Quartz

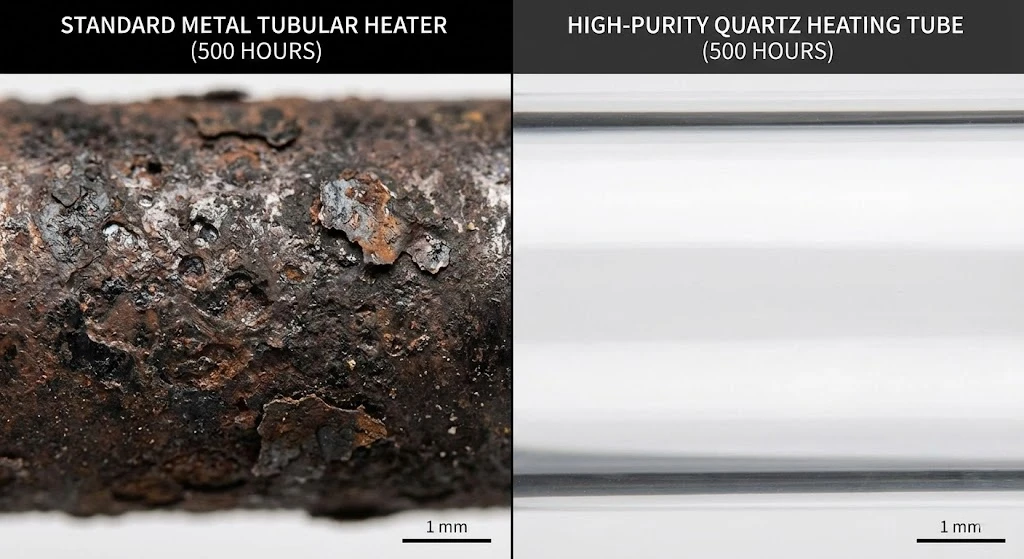

Why are advanced medical OEMs moving away from traditional sheathed metal heating elements (like stainless steel tubular heaters) and adopting quartz infrared technology? The answer lies in material science.

1. Zero Outgassing & Particle-Free Operation

Traditional stainless steel or Incoloy heaters undergo severe thermal expansion and contraction during operation. Over thousands of cycles, the metal surface inevitably oxidizes, leading to microscopic “flaking” or scaling. In a sterile incubator or a cleanroom laboratory oven, these airborne metallic particulates are unacceptable contaminants.

A high-purity quartz envelope, even when operating at internal temperatures exceeding 1000°C, remains perfectly smooth and chemically inert. It does not rust, it does not flake, and it emits absolutely zero volatile organic compounds (VOCs) or metallic dust into the airstream.

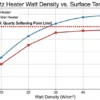

2. Low Thermal Mass & Overshoot Prevention

When heating biological samples—particularly human blood, intravenous (IV) fluids, or protein-based medications—temperature overshoots are lethal. Proteins denature rapidly if exposed to temperatures even slightly above their strict thermal limits.

- The Metal Problem: Metal heaters possess high thermal mass. When the thermostat cuts the power, the heavy metal continues to radiate stored heat for several minutes, causing a dangerous temperature spike (overshoot) in the fluid or chamber.

- The Quartz Solution: Quartz infrared heaters have extremely low thermal inertia. The moment the electrical current is cut, the radiant heat output drops instantly. When paired with a high-resolution PID controller or a solid-state relay (SSR), a quartz heater allows medical engineers to achieve and maintain temperature stability with a precision of ±0.1℃, ensuring biological viability.

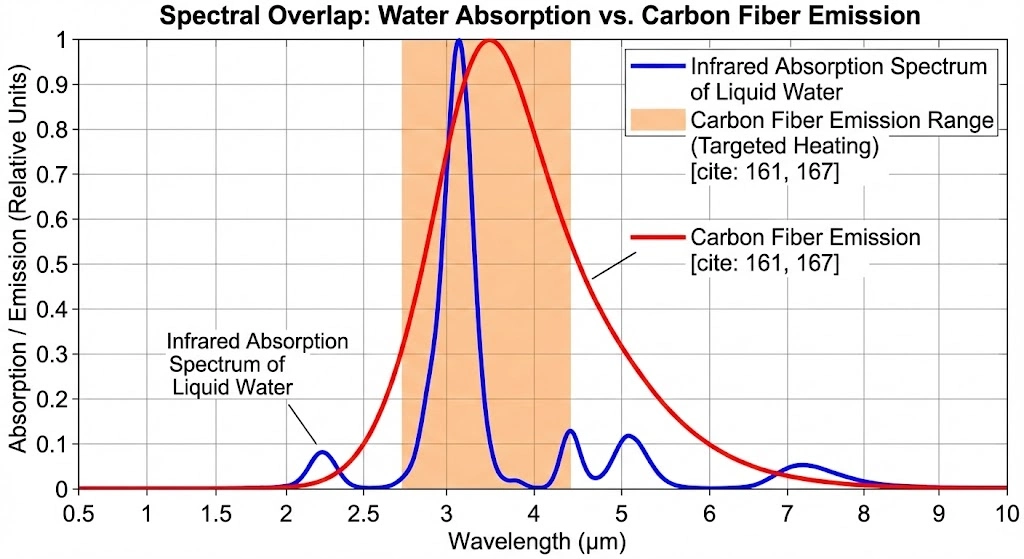

Cell-Level Heating: Matching the Biological Absorption Spectrum

In medical device design, heating must follow the principle of Targeted Heating. You do not want to aggressively heat the plastic housing of the device or the glass of the petri dish; you want to safely transfer energy directly to the biological subject.

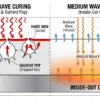

1. Medium Wave (Carbon Fiber) for Biological Fluids

The primary constituent of human tissue, blood, and most intravenous pharmacological fluids is water (H2O). Water molecules exhibit a massive, natural resonance (absorption peak) in the infrared spectrum between 2.5 μm and 3.0 μm.

- The Application: By utilizing a Carbon Fiber Quartz Heater (which emits Medium Wave infrared peaking precisely in this band), the energy is absorbed directly and gently by the fluid molecules. It does not pierce through the fluid to scorch the container, nor does it bounce off. It provides deep, volumetric, and exceptionally safe warming for blood warmers and dialysis machines.

2. Short Wave (Halogen) for Deep Sterilization

Conversely, if the objective is not to warm a patient but to rapidly incinerate pathogens inside a dry heat sterilizer, engineers utilize Short Wave Halogen Emitters (peaking around 1.0 μm – 1.2 μm). These high-energy photons penetrate deep into the microscopic crevices of surgical instruments or glass vials, elevating the temperature to 190°C in seconds to ensure absolute biological eradication.

The Big Three: Specific Medical Device Applications

1. Infant Incubators & Neonatal Radiant Warmers

- The Requirement: The heat must be incredibly gentle, absolutely stable, and free from blinding visible light that could damage a premature infant’s developing retinas.

- The OEM Solution: We specify Ruby Quartz Heaters paired with a Half-Ceramic White reflector, or low-watt-density Carbon Fiber tubes. The ruby doping filters out harsh visible glare, providing a soft, comforting dark-red glow, while the ceramic reflector safely directs the gentle medium-wave heat downward onto the mattress area without heating the overhead canopy.

2. High-Temperature Dry Heat Sterilization (Depyrogenation)

- The Requirement: The sterilization chamber must reach 160°C to 190°C rapidly, and the thermal field must be absolutely uniform to ensure no “cold spots” where bacterial spores could survive.

- The OEM Solution: We manufacture custom U-Shape or Omega (Ω) Shape Halogen Twin Tubes. By contouring the heater to trace the exact perimeter of the sterilization chamber, we eliminate corner cold spots and guarantee uniform pathogen destruction across every square inch of the payload.

3. Blood & IV Fluid Warmers

- The Requirement: The internal chassis space is microscopic. The heater must rapidly warm flowing fluids from refrigerated temperatures to exactly 37°C without a single degree of overshoot, and electrical leakage is strictly prohibited.

- The OEM Solution: We produce Miniature Single-Ended Quartz Heaters with ultra-fast thermal response times. With diameters customizable down to 6mm or 8mm, these micro-emitters slide seamlessly into compact heat-exchanger blocks.

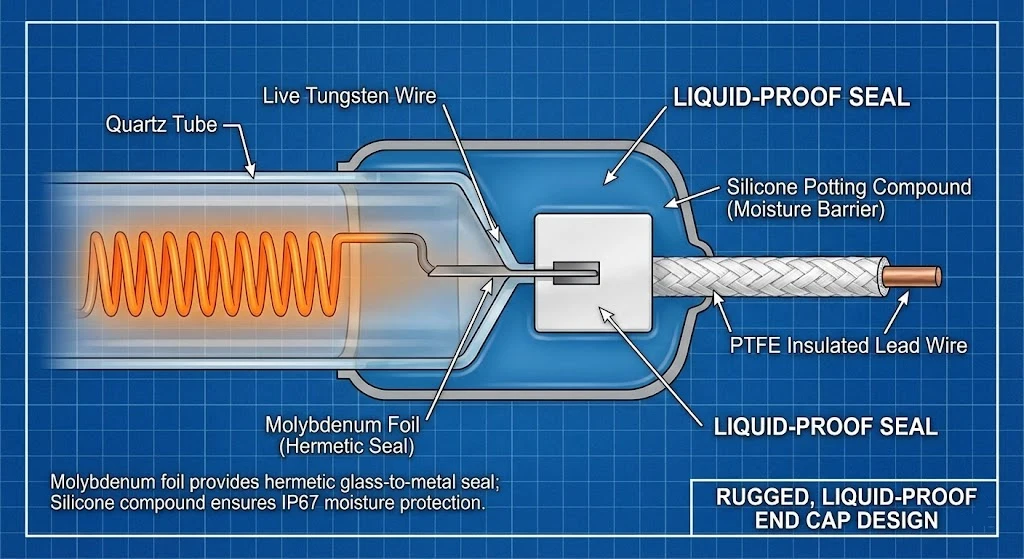

Electrical Safety & Compliance: The IEC 60601-1 Standard

Designing a medical device means navigating a labyrinth of strict international safety regulations, most notably the IEC 60601-1 standard for medical electrical equipment. The primary concern? Leakage Current.

1. Superior Dielectric Strength

If a fluid bag leaks inside a medical device, a compromised heating element could transfer lethal voltage to the patient or operator. Quartz glass (Silicon Dioxide) is one of the most effective natural electrical insulators (dielectrics) known to science. It physically completely isolates the live high-voltage tungsten filament from the external environment, ensuring exceptional hipot (high potential) test pass rates and virtually eliminating chassis leakage current.

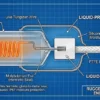

2. Hermetic Cold Pin Sealing

The weakest link in any heater is where the electrical wires enter the tube. For medical OEMs, we utilize an advanced hermetic sealing process.

- The Structure: We employ a high-temperature molybdenum foil seal encased within a precision ceramic insulator. We then encapsulate the entire termination in medical-grade silicone potting and utilize high-dielectric PTFE (Teflon) or fiberglass insulated lead wires. This multi-stage sealing architecture guarantees that condensation, cleaning chemicals, or bodily fluids cannot penetrate the element and cause a short circuit.

OEM Integration in Compact, Space-Restricted Environments

Medical devices—from portable transport incubators to tabletop blood analyzers—are shrinking. Internal real estate is incredibly expensive.

In these portable devices, there is simply no physical room to install external, bulky stainless-steel parabolic reflectors behind the heating elements to direct the heat. Furthermore, if you allow a bare quartz tube to radiate 360° inside a tiny plastic chassis, the rearward-facing radiation will quickly melt the enclosure or fry the delicate adjacent PCB motherboards.

The Space-Saving Solution: By sintering a highly reflective 180° Gold Coating directly onto the back half of a miniature (e.g., 10mm diameter) quartz tube, we solve both problems simultaneously. We compress an entire directional heating assembly into a single, tiny component. The gold layer acts as a thermal shield, protecting the sensitive electronics behind the heater, while focusing all the radiant energy precisely where the biological process requires it.

FAQ: Questions from Medical Device R&D Engineers

Are quartz infrared heaters safe to use in oxygen-enriched environments like infant incubators?

Yes, they are intrinsically safe for these applications. Because the glowing filament is hermetically sealed within the vacuum or inert gas environment of the quartz tube, there is absolutely no exposed ignition source to interact with the oxygenated atmosphere.

Can your quartz infrared heaters withstand harsh hospital sterilization protocols?

Absolutely. The exterior of the quartz envelope is non-porous and chemically inert. It can withstand repeated exposure to Vaporized Hydrogen Peroxide (VHP) fogging, harsh chemical wipe-downs (bleach/alcohol), and intense ambient UV-C irradiation without suffering any structural or optical degradation.

What is the minimum physical diameter for a custom medical-grade quartz heater?

At Hongtai, our specialized manufacturing capabilities allow us to produce highly compact miniature quartz emitters with outside diameters as small as 6mm or 8mm. We can configure these micro-heaters with specialized single-ended wiring to fit into the tightest medical fluid warming cassettes or optical analysis chambers.

Conclusion: In Medical Engineering, Precision is Not Optional

The thermal control system within a medical device cannot be “good enough.” Every physical parameter—from the zero-outgassing properties of the quartz envelope to the exact micron wavelength of the medium-wave radiation—directly impacts patient safety, biological efficacy, and FDA compliance.

Navigating FDA or CE Medical Device Certification?

Do not risk your compliance testing on generic, commercial-grade heating elements. Send your thermodynamic requirements, chassis spatial constraints, and target biological materials to the Hongtai Thermal Engineering Department. We will partner with your R&D team to engineer a custom, compliance-ready Medical Infrared Heater that passes inspection and performs flawlessly.

[Consult a Hongtai Engineer for Your Medical Device OEM Project]