Introduction & The Cold Spot Dilemma

If you design high-performance industrial automation equipment, you are intimately familiar with the “Cold Spot” dilemma.

You are tasked with engineering a complex thermal process—perhaps vacuum-forming 3D automotive door panels, shrinking polymer tubing over circular pipes, or curing adhesive on a rapidly moving, irregularly shaped conveyor belt.

When you attempt to heat these complex 3D geometric parts using standard, straight-line infrared heaters, physics fights against you. Thermal radiation follows the inverse-square law; the distance from the emitter to the target drastically affects the intensity of the heat absorbed.

If your product is curved but your heater is straight, the product’s center closest to the lamp will blister and scorch, while the outer edges remain stubbornly cold, leading to immediate forming failures or uncured coatings.

The definitive engineering solution to cold spots is 3D Thermal Profiling. You must abandon the straight line and bend the heat source to wrap around the target. By utilizing a Custom Shaped Quartz Heater, you ensure uniform watt density absorption across the entire surface area of the product, regardless of its topography.

While customizing the geometry solves spatial issues and thermal gradients, you must first ensure your filament choice matches the material’s absorption rate. Verify your spectrum requirements in our Industrial Quartz Heating Tubes: The Complete Engineering Guide before finalizing any CAD drawings.

Why the Twin Tube is the Gold Standard for Industrial Ovens

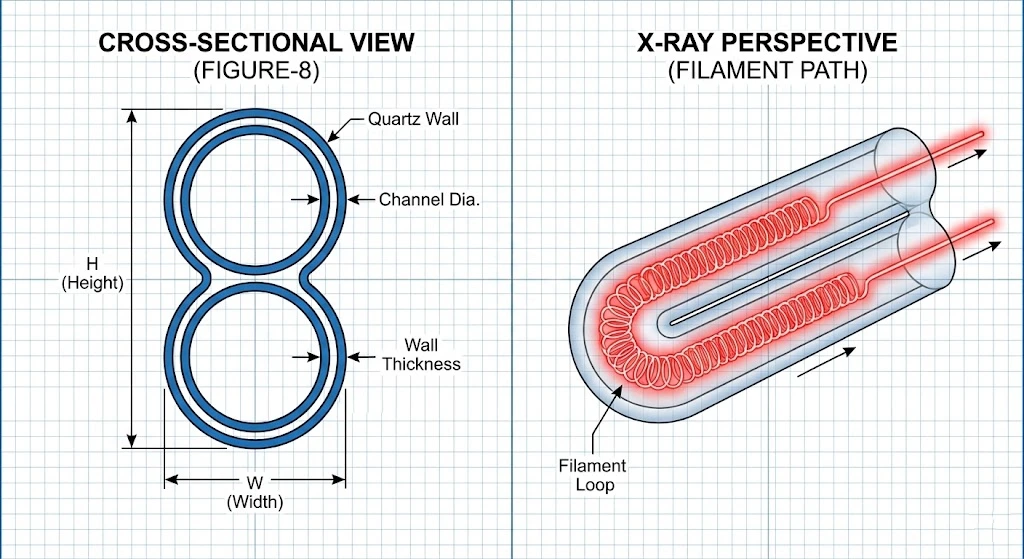

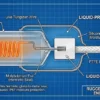

When discussing custom shapes, we must begin with the foundation of heavy industrial infrared design: the Twin Tube (or Double Tube). A twin tube is constructed by fusing two separate quartz tubes together longitudinally, creating a cross-section that resembles a figure-8. It is not simply two straight tubes glued together; it is a fundamental architectural upgrade.

1. Mechanical Rigidity for Long Spans

At operating temperatures exceeding 1000°C, the silica glass of a standard single quartz tube can become slightly ductile. Over long spans (e.g., 2000mm to 3000mm in a wide-web paper drying oven), a single tube will inevitably sag under its own weight if installed horizontally.

The twin tube’s figure-8 geometry acts like an industrial I-beam. This “H-profile” provides immense structural stiffness and anti-bending rigidity, allowing engineers to specify massive, high-power emitters that remain perfectly straight without the need for complex internal support brackets that would block the infrared radiation.

2. The Magic of Single-Ended Wiring

For electrical engineers and panel builders, the twin tube solves a massive logistical headache.

In a standard single-tube installation, you must route high-temperature, high-voltage wiring to both sides of the oven enclosure. This doubles the required insulation, ceramic standoff blocks, and labor time.

A twin tube features a continuous “U-shaped” filament inside. The electrical current enters the top chamber, travels the full length of the tube, loops around at the far end, and returns via the bottom chamber.

- The Result: Both the positive and negative electrical connections are located on the exact same side of the tube. This Single-Ended Connection drastically simplifies oven wiring logic, cuts cabling costs by 50%, and makes rapid maintenance replacements a one-sided operation.

U-Shape and Omega ($\Omega$) Shape: Compensating for the Edge Effect

When heating flat sheets of plastic for thermoforming, engineers must battle the “Edge Effect.”

1. Understanding the Edge Effect

Thermodynamically, the perimeter of a flat plastic sheet dissipates heat into the ambient air much faster than the center of the sheet. Furthermore, the clamping frame holding the plastic often acts as a massive heat sink, drawing thermal energy away from the edges. If you apply a perfectly uniform blanket of heat across the entire sheet, the center will reach its glass transition temperature while the edges remain rigid, resulting in tearing during the molding process.

2. The U / Ω Compensation Mechanism

To counteract the edge effect, engineers utilize custom U-Shape or Omega (Ω) Shape quartz heaters.

Instead of relying on a grid of straight tubes, we bend the quartz envelope to concentrate a higher density of tungsten or carbon fiber filament directly along the perimeter of the heating zone. By actively forcing more watt density ($W/cm^2$) into the high-loss areas, we can achieve an absolutely uniform temperature profile ($\Delta T < 2^\circ C$) across the entire target material.

Whether you require the instant, deep-penetrating power of Short-Wave Halogen or the highly absorptive, soft heat of Medium-Wave Carbon Fiber, both technologies can be seamlessly integrated into custom bent envelopes.

Pear Shapes and 360° Circular Emitters: Wrapping the Cylinder

If your target product is a cylinder, a wire, or a pipe, using straight heating elements is an exercise in inefficiency.

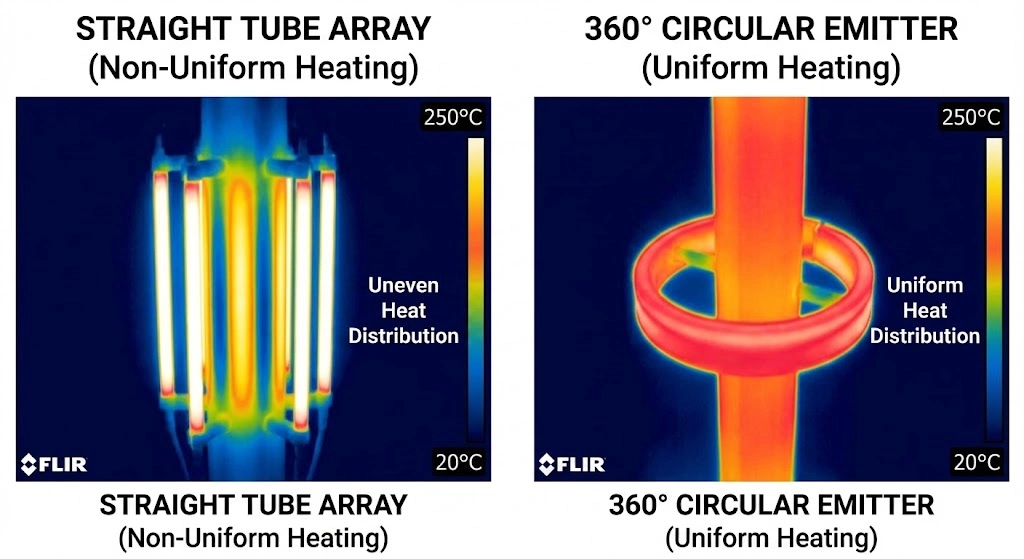

1. The Flaw of the Straight Array

Many equipment builders attempt to heat a pipe by building a hexagonal or octagonal tunnel out of 6 to 8 straight quartz tubes. This creates intense “hot spots” where the straight tubes are closest to the curved pipe, and significant “cold valleys” in the gaps between the tubes.

2. The Circular Element Solution

The optimal approach is to use a true Circular Tube or Pear Shape heater. We manufacture quartz heating elements that are bent into a continuous 360° ring. The product passes straight through the center of the ring, absorbing perfectly uniform, omnidirectional radiation from all sides simultaneously.

Ideal Applications Include:

- High-speed curing of electrical cable insulation.

- Automated shrinking of heavy-duty heat shrink tubing.

- Medical catheter tip forming and bonding.

- Pre-heating metallic pipes before welding or coating.

The Hongtai Manufacturing Capability: The Art of Bending Quartz

Why do many suppliers only offer straight tubes? Because bending quartz glass without destroying the internal components is an incredibly difficult, high-barrier manufacturing process.

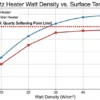

1. The Softening Point Challenge

Unlike standard borosilicate glass or Pyrex, high-purity silica quartz has an exceptionally high softening point of approximately 1600°C (2912°F).

To achieve a custom bend, our technicians must heat the specific nexus point of the tube to 1600°C using specialized oxy-hydrogen torches. Simultaneously, they must ensure that the delicate, hair-thin tungsten or carbon fiber filament inside the tube is neither oxidized by the intense heat nor snapped by the mechanical stress of the bending radius. This requires master-level craftsmanship and precise CNC-assisted rotary manipulation.

2. Vacuum & Halogen Gas Injection

Bending a tube is only half the battle. Once the custom shape is formed, the integrity of the internal environment must be restored. Every custom shaped quartz heater produced by Hongtai undergoes a rigorous vacuum evacuation process. We then precisely inject high-purity inert argon gas (for carbon fiber) or a specific halogen gas mixture (for tungsten), ensuring the heater delivers its full 5,000 to 8,000-hour operational lifespan without filament degradation.

Reflector Integration on Custom Shapes

A common question from engineers is: “If I order a custom U-shape or a Twin tube, can I still get a reflector to direct the heat?”

Yes. Absolutely.

Even on highly complex geometric shapes, the Hongtai facility has the capability to apply and sinter high-efficiency reflectors directly onto the rear hemisphere of the bent quartz.

Whether you require the 95%+ reflectivity of our Gold (Half-Gold Plated) coating for maximum efficiency, or the robust 900°C heat resistance of our Ceramic White Processing coating, we can permanently bond these reflectors to your custom tube. This allows you to take 360° of scattered energy and focus it into a tight, 180° directional heat beam exactly where your complex product needs it most.

FAQ: Custom Engineering Questions

What is the minimum bend radius for a custom shaped quartz heating tube?

The minimum bend radius is strictly dictated by the outside diameter (OD) of the quartz tube itself. As a general engineering rule of thumb, the internal bend radius must be at least 2.5 to 3 times the diameter of the tube. For example, a 10mm OD tube will typically require a minimum bend radius of 25mm to 30mm to prevent the glass wall from collapsing or thinning dangerously during the heating process.

Can carbon fiber medium-wave heaters be made into custom shapes?

Yes. In fact, carbon fiber is exceptionally well-suited for custom geometries. Because it is a woven, flexible textile filament rather than a rigid coiled metal wire, it can be easily contoured into tight U-shapes, Pear shapes, or Circular rings without suffering from the stress concentrations that can plague metallic filaments during the bending process.

Does bending the tube into a custom shape affect the lifespan of the heater?

If manufactured correctly, a custom shape does not reduce the lifespan. Provided the bend radius adheres to engineering limits, the quartz wall thickness remains uniform, and the tube is properly evacuated and re-filled with the correct protective gas, a custom U-shape or Twin tube will deliver the exact same 5,000 to 8,000-hour lifespan as its straight counterpart.

Conclusion: Let the Heater Adapt to the Machine

Standardized, off-the-shelf straight tubes can only solve 80% of industrial heating challenges. In the fiercely competitive landscape of custom machine building and non-standard automation, that remaining 20%—the absolute uniformity of your thermal profile—is what dictates the speed, reliability, and ultimately the selling price of your equipment.

Shape the heater to the product, not the product to the heater.

Stop compromising the design of your oven enclosure or accepting high scrap rates due to cold spots. Send your STEP, IGES, or DWG CAD files to the Hongtai Thermal Engineering Department. Within 48 hours, our experts will provide a comprehensive feasibility study, bending radius verification, and a prototyping plan for your Custom Shaped Quartz Heaters.