Introduction & The Glare Problem

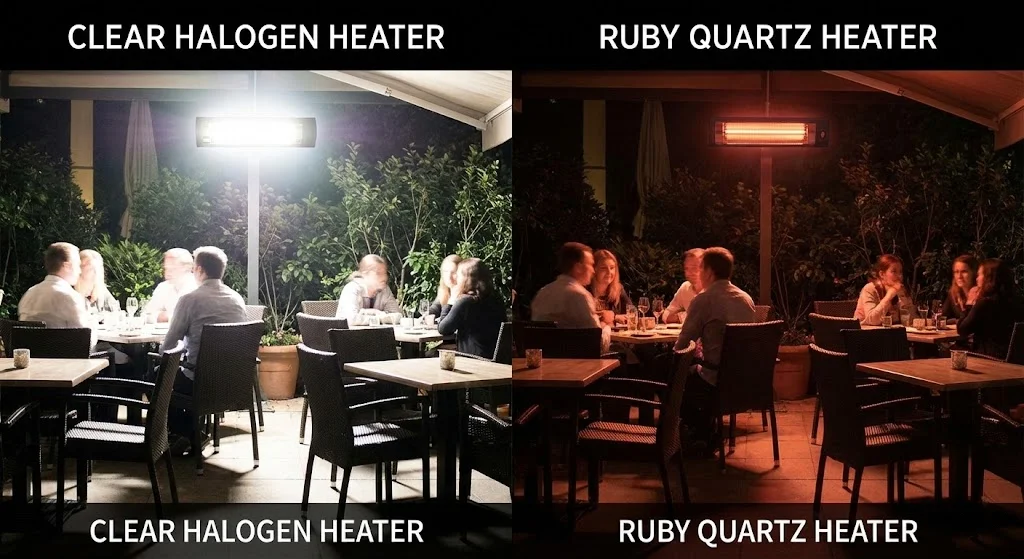

When it comes to sheer thermodynamic speed and high-density power, the halogen short-wave infrared heater is unrivaled. It can reach peak operating temperatures of 2400K in under a second. However, this immense power comes with an inherent optical byproduct: intense, blinding white light.

If you are an Original Equipment Manufacturer (OEM) designing a high-end patio heater for a restaurant, or an EHS (Environmental Health and Safety) manager overseeing a manual inspection line, this is a massive problem. A standard clear halogen tube acts less like a heater and more like a high-intensity floodlight. It causes severe eye fatigue, ruins the ambient atmosphere of commercial spaces, and can even create safety hazards for workers.

You want maximum heat. You do not want a searchlight.

The engineering solution is the Ruby Red Quartz Heating Tube. This element acts as a precision optical filter—perfectly blocking harsh visible glare while allowing pure infrared thermal energy to pass through unabated.

Engineering Context: Understanding the baseline properties of quartz glass is essential before exploring optical filters. For a comprehensive overview, read our Industrial Quartz Heating Tubes: The Complete Engineering Guide.

The Physics of Ruby Filtration: Passing Heat, Blocking Light

It is a common misconception that a ruby heater is simply a clear tube painted red. In industrial applications, surface paint would burn off within minutes at 1000°C.

1. Doped Quartz Glass

True ruby quartz heaters are manufactured using Doped Quartz Glass. During the melting and extrusion process of the silica, specific trace elements (such as rare-earth compounds or metallic oxides) are infused directly into the molecular structure of the glass. This intrinsic doping permanently alters the optical properties of the tube.

2. Spectral Transmittance

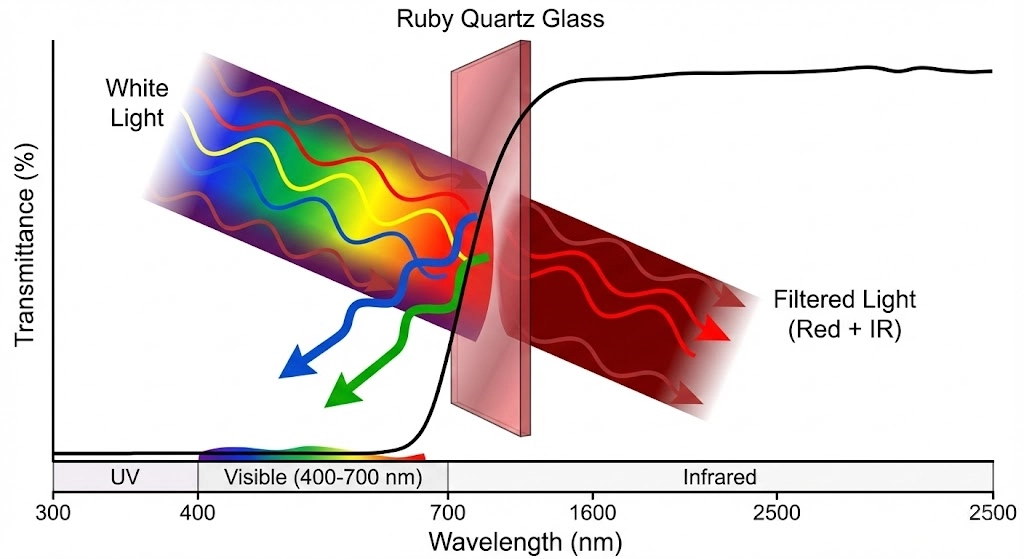

The resulting ruby glass acts as a highly effective band-pass filter.

- The Block: It aggressively absorbs radiation in the visible spectrum between 0.4μm and 0.7μm—specifically targeting the harsh blue, green, and bright yellow wavelengths that cause human eye strain.

- The Pass: Meanwhile, its transmittance in the critical infrared heating bands (0.8μm to 2.5μm) remains incredibly high, often exceeding 90%.

The physics are simple: The visible light is trapped; the thermal energy is released.

Technical Specifications: Building Your Low-Glare System

For engineers and procurement teams, integrating ruby quartz into your product line is seamless.

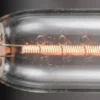

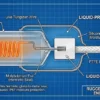

1. The Internal Engine: Halogen Tungsten

Inside the ruby casing, we typically utilize a Halogen Tungsten filament. This gives you the best of both worlds: the instant on/off response time (<1 second) and high watt density of tungsten, entirely tamed by the ruby filter to eliminate the blinding flash upon startup.

2. Voltage & Power Flexibility

We manufacture these elements to accommodate global electrical standards.

- Voltage Range: Fully customizable to 110V, 120V, 220V, 230V, 240V, 400V, and 480V.

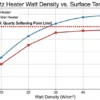

- Power Density: Available from 300W up to 3000W per tube, with lengths ranging from a compact 100mm to an expansive 2000mm.

- Operating Temperature Range: Engineered to operate stably between 1°C and 1400°C.

3. The Ultimate Combo: Ruby + Gold Reflector

For premium OEMs, we offer the ultimate thermal configuration: A Ruby Quartz tube with a Half-Gold Plated Reflector sintered onto the back. This combination achieves two goals simultaneously:

- Low Glare: The ruby glass ensures a soft, comfortable red glow.

- Directional Efficiency: The gold reflector captures the rearward-radiating heat and focuses it 180° forward onto the patio guests or the product, increasing effective thermal output by up to 35% without increasing wattage.

Commercial & OEM Applications: Upgrading Your Premium Range

In the B2B2C market, the heating element you choose directly dictates the retail price and user experience of your final product.

1. Patio & Alfresco Dining Heaters

In the hospitality industry, ambiance is revenue. Customers want to feel the warmth of a fire, not the interrogation glare of a surgical lamp. Ruby quartz heaters emit a deep, warm, fireplace-like glow. Upgrading from a clear halogen tube to a ruby element instantly elevates a standard patio heater into a premium, high-margin architectural appliance.

2. Medical & Infrared Saunas

In therapeutic environments like infrared sauna cabins, the visual experience must be relaxing. A ruby quartz element removes the harsh optical stimulation of bright light. Furthermore, because it utilizes high-purity quartz and operates cleanly via radiation, it produces zero dust, zero odor, and zero noise—perfect for cleanroom or wellness applications.

Industrial Low-Glare Necessities

While aesthetics drive the commercial market, occupational health and process control drive the industrial demand for ruby quartz.

1. Manual Intervention Assembly Lines

Consider a conveyor system where workers must visually inspect wet paint, soldering joints on PCBs, or perform color-matching under the heat source. If the drying lamps are clear 2400K halogens, the workers will suffer from severe eye strain, headaches, and ultimately, decreased inspection accuracy. Ruby quartz provides the intense drying heat required while protecting the workers’ vision and preventing color-washout on the product.

2. Light-Sensitive Material Processing

Certain advanced manufacturing processes—such as curing photosensitive resins, specialized adhesives, or photographic films—require thermal energy but are highly reactive to ultraviolet (UV) or short-wave visible blue light. A standard clear halogen lamp will trigger premature curing or chemical degradation. Ruby quartz acts as a thermal safe-light, delivering pure heat without initiating unwanted photochemical reactions.

End-Caps & Customization: Designed for the Assembly Line

We understand that for an OEM, ease of assembly is just as critical as thermal performance. We custom-manufacture the terminations of our ruby tubes to integrate perfectly into your existing housing designs.

Common Custom Terminations Include:

- SK15 / R7s: Standard snap-in ceramic end caps for rapid assembly and easy end-user replacement.

- Flying Leads: High-temperature insulated wire leads (PTFE or fiberglass) custom-cut to your required length, eliminating the need for complex internal routing.

- Mounting Options: Engineered for both Horizontal and Vertical operation, providing total freedom for your industrial design team.

FAQ: Common Questions on Ruby Heating Elements

Does the ruby coating reduce the heat output?

The reduction is negligible. The ruby doping is specifically engineered to block visible light photons, not infrared photons. Since the vast majority of the energy generated by the tungsten filament is in the infrared spectrum, the total thermal loss is typically less than 5%.

Can I use a ruby heater instead of a carbon fiber heater?

It depends on your primary goal. If you need instant heat (<1 second response) combined with low glare (e.g., a patio heater that turns on via a motion sensor), a Ruby Halogen tube is the best choice. If your process allows for a slower heat-up time (3-5 seconds) and you are drying water-based paints or plastics, a Carbon Fiber tube (which is naturally low-glare) offers better wavelength absorption.

What is the lifespan of a ruby quartz heating element?

Under standard operating conditions with stable voltage, the lifespan exceeds 5000 hours. Because we utilize specialized vibration-resistant tungsten filament designs, they are highly durable even in commercial settings.

Conclusion: Maximum Heat, Minimum Glare

In the competitive landscape of commercial heating and industrial process design, details matter. Upgrading a standard, blinding clear heater to a Ruby Quartz element is the fastest, most effective way to improve user ergonomics, ensure worker safety, and command a premium price for your final product.

Designing a new patio heater line or upgrading a manual inspection station? Do not let harsh glare ruin your product’s appeal. Contact Hongtai, send us your enclosure dimensions, and our engineering team will calculate the optimal wattage and supply a Ruby Quartz prototype to accelerate your CE/UL safety testing.