Introduction

The “Technical Insight” Hook:

Did you know that a standard 2400K halogen heater wastes nearly 40% of its energy when curing clear plastics? It’s not a defect in the heater; it’s physics. Most clear polymers are transparent to short-wave radiation—meaning the heat passes right through the material instead of being absorbed by it.

In industrial heating, 1000 Watts isn’t always 1000 Watts of usable heat. The difference lies in Spectral Matching.

As manufacturers push for higher efficiency standards in 2026, whether you are retrofitting a PET blow molding line or designing a semiconductor wafer drying system, selecting the correct Quartz Heating Tube is the single most critical factor in your thermal process’s success.

Content Roadmap: What You Will Learn

- The Physics of Efficiency: Why wavelength matching matters more than raw wattage.

- Filament Wars: A technical comparison of Halogen (Short Wave) vs. Carbon Fiber (Medium Wave).

- Advanced Optics: How gold reflectors can boost directional efficiency by 35%.

- Application Guide: Specific recommendations for Plastics, Paint, and Photovoltaics.

Why 50% of Industrial Heating Systems Are Wasting Energy (The Spectral Mismatch Problem)

Walk into many factories today, and you’ll see a common inefficiency: short-wave halogen lamps being used to heat water-based coatings, or long-wave ceramic heaters trying to keep up with a high-speed assembly line.

This is a classic case of Spectral Mismatch.

Every material—from PVC to water to steel—has a unique Absorption Spectrum. It absorbs radiation efficiently only at specific wavelengths. If your emitter’s peak wavelength doesn’t align with your material’s absorption peak, you are essentially heating the air, the machine frame, or the floor, but not your product.

Definition:

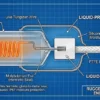

What is an Industrial Quartz Heating Tube?

It is a high-purity quartz glass emitter that transmits infrared energy generated by an internal filament (Tungsten or Carbon Fiber). Operating between temperatures of 1200K and 2500K, these tubes emit specific wavelengths (0.78–4.0μm) designed to match the absorption characteristics of the target material for maximum thermal transfer efficiency.

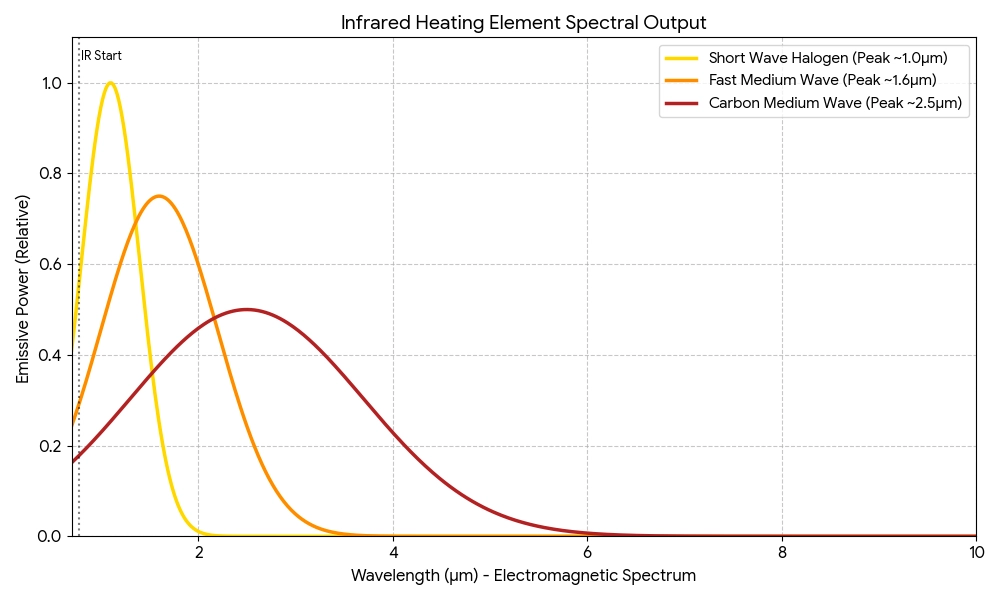

Understanding the IR Spectrum: Wavelength vs. Temperature

To choose the right heater, we must first look at the physics. The relationship between an emitter’s temperature and its peak wavelength is governed by Wien’s Displacement Law:

{max} = 2898/T

Where:

- {max} is the peak wavelength in microns (μm).

- T is the temperature of the filament in Kelvin (K).

The Core Principle: The hotter the filament, the shorter the wavelength.

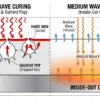

- Short Wave (SW): High temperature (2400K+). Acts like a “needle”—high penetration power. Excellent for metals or thick layers that need internal heating.

- Medium Wave (MW): Moderate temperature (~1200K). Acts like “water”—efficiently absorbed by surfaces. Ideal for drying coatings, plastics, and paper.

Filament Technologies: Halogen vs. Carbon Fiber

Choosing between Halogen and Carbon Fiber isn’t about cost—it’s about response time and absorption.

1. Halogen / Tungsten Quartz Tubes (Short Wave)

- Peak Wavelength: 0.8 – 1.8 μm

- Color Temperature: 2400 – 2500 K

- The Technology: A tungsten filament is sealed in a quartz tube filled with halogen gas. The halogen cycle redeposits evaporated tungsten back onto the filament, preventing tube blackening.

- Core Advantage: Instant Response. These tubes reach full power in under 1 second. This makes them indispensable for processes that require frequent start-stop cycles, such as PET bottle blowing or high-speed paper drying.

- Engineering Challenge: Inrush Current. The cold resistance of tungsten is extremely low. Upon startup, the current can spike to 10–15 times the nominal rating. Your SCR power controllers must be sized to handle this surge.

2. Carbon Fiber Quartz Tubes (Medium Wave)

- Peak Wavelength: 2.0 – 4.0 μm

- Color Temperature: ~1200 K

- The Technology: Uses a woven or spiral carbon filament.

- Core Advantage: Absorption Efficiency. Most organic materials (plastics, polymers) and water molecules absorb energy best in the medium-wave region (2.5–3.5 $\mu m$). Carbon fiber heaters provide a “softer” heat that cures coatings without blistering the surface (the “Orange Peel” effect).

- Bonus: No Inrush Current. The resistance of carbon fiber is stable, simplifying electrical design.

Quick Selection Guide: Halogen vs. Carbon Fiber

| Feature | Halogen (Short Wave) | Carbon Fiber (Medium Wave) |

| Response Time | < 1 Second (Instant) | 2 – 4 Seconds |

| Peak Wavelength | ~1.0 μm | ~2.5 – 3.0 μm |

[Interactive Check]:

Do you need instant on/off capabilities for a synchronized production line?

[ ] Yes → Recommend Halogen.

[ ] No → Evaluate Carbon Fiber for better absorption.

Not All Tubes Are Transparent: Coatings & Reflectors

Once you select the filament, you must control where the energy goes. Standard clear quartz tubes emit radiation 360° radially. Without a reflector, 50% of your energy heats the machine housing behind the tube.

1. Gold Reflector (The Efficiency Booster)

By applying a thin layer of gold directly onto the quartz tube, we create a Directional Heater. Gold reflects over 95% of infrared radiation.

- Effect: Concentrates heat into a 180° forward beam.

- Result: Effective energy on the product increases by 30–40% compared to bare tubes.

- Limit: Standard gold coating degrades above 600°C. For higher temperature environments, specific cooling protocols are required.

2. Ceramic White (High-Temp Reflector)

For applications where the ambient temperature exceeds 600°C (such as in glass bending ovens), gold coatings may peel or degrade. A Ceramic White reflector is the solution. It offers slightly lower reflectivity (~85-90%) but withstands temperatures up to 800-1000°C.

3. Ruby Red (Glare Reduction)

Halogen lamps are bright. In factories with human operators, the intense white light can cause eye fatigue. Ruby Quartz filters out most visible light while letting infrared heat pass through. Ideal for comfort heating or visual inspection zones.

Geometry & Customization: Shaped for Your Thermal Field

Standard straight tubes work for flat conveyors. But what if your product is a complex 3D shape?

- Twin Tube (The “Figure 8”): Two tubes fused together. This design offers superior mechanical strength (less sagging at length) and allows for single-ended electrical connections, simplifying wiring in tight spaces.

- Omega ( Ω ) & U-Shapes: Critical for industrial thermoforming or drying pipelines where the heater must wrap around a mold or a fluid pipe.

Vertical Applications: Which Tube for Your Process?

Here is the “Cheat Sheet” for industry-specific selection:

1. Plastics & Thermoforming

Recommendation: Medium Wave (Carbon Fiber) or Fast Medium Wave.

- Why: Plastics have complex hydrocarbon bonds that absorb energy strongly between 3.0–3.5 μm. Short wave radiation often penetrates too deeply, overheating the internal structure while leaving the surface too cool for forming.

2. PET Bottle Blowing

Recommendation: Short Wave (Halogen).

- Why: PET preforms are thick and need deep, penetrating heat in seconds to soften uniformly before blowing. The fast cycle time of bottling machines also demands the instant on/off response of halogen.

3. Automotive Paint Curing

Recommendation: Hybrid Approach.

- Why: Use Short Wave to preheat the metal body (substrate) and Medium Wave to cure the paint from the outside in. This prevents solvent trapping and bubbles.

4. Photovoltaics & Semiconductors

Recommendation: High-Purity Transparent Quartz.

- Why: These industries require Class 100 cleanroom standards. Our tubes use high-purity quartz sands to minimize metallic contamination during the wafer drying process.

Engineer’s Guide: Installation & Maintenance

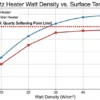

To ensure you get the rated 5000+ hour life from your heaters:

- Orientation Matters: Halogen/Tungsten tubes generally must be installed horizontally. Vertical installation causes the tungsten wire to sag and coil upon itself, leading to immediate failure. If you need vertical heating, specify a heater with “pinch points” or internal supports, or switch to Carbon Fiber (which can be mounted vertically).

- The “Glove Rule”: Never touch quartz glass with bare hands. Salt and oils from your skin create “hot spots” that cause Devitrification (crystallization) of the quartz, turning it milky white and brittle. Always use cotton gloves.

- Cooling: If your power density exceeds 100 W/cm, forced air cooling at the ceramic ends is mandatory to protect the electrical seals.

FAQ: Common Technical Questions

What is the difference between a Quartz Heater and a Ceramic Heater?

Quartz Heaters respond instantly (1-2 seconds) and heat primarily via radiation, making them efficient for conveyor systems and spot heating. Ceramic Heaters have high thermal mass (slow to heat up/cool down) and emit long-wave radiation, better suited for static ovens requiring uniform, non-directional ambient heat.

Is the lifespan of a halogen tube really 5000 hours?

The theoretical design life is 5000 hours. Real-world longevity depends on voltage stability, shock/vibration, and starting frequency. Using a “Soft Start” voltage ramp can significantly extend life by mitigating inrush current damage.

Why did my quartz tube turn milky white?

This is Devitrification. It usually happens when surface contaminants (dust, oil, fingerprints) react with the silica at high temperatures (>1000°C), breaking down the amorphous glass structure. Keep tubes clean!

What is the maximum temperature for a Gold Reflector?

We recommend keeping the reflector body below 600°C. Above this, the gold layer may begin to diffuse into the quartz or peel. For higher temperature furnaces, choose Ceramic White (Half-White) coatings.

Stop Guessing, Start Engineering

There is no “best” heating tube—only the one whose wavelength matches your material.

If you are seeing high rejection rates, slow line speeds, or excessive energy bills, the problem likely isn’t the machine; it’s the emitter.

Talk to a Thermal Engineer & Get Your Custom Heating Profile.

Don’t just buy a spare part. Send us your material specs (type, thickness, target temp), and we will calculate the exact peak wavelength and power density required for your process.