Introduction

In industrial thermal processing, a cartridge heater is often viewed as a simple commodity. However, for the maintenance manager facing a line shutdown or the R&D engineer designing a high-speed packaging die, these components are anything but simple.

Premature burnout, uneven heating, and seized elements are rarely “bad luck”—they are usually the result of a mismatch between the heater’s specifications and its operating environment. This guide dismantles the complexities of cartridge heater engineering, focusing on the 2026 standards for watt density, material science, and fit tolerance. By following these principles, you can expect to increase the MTBF (Mean Time Between Failure) of your heating elements by over 30%.

1. What is a Cartridge Heater? (Principles and Anatomy)

A cartridge heater is a heavy-duty tube-shaped industrial heating element (electrical resistance) used primarily in the process heating industry, usually custom manufactured to a specific watt density, based on its intended application.While the exterior looks like a simple metal rod, the interior is a high-precision thermal engine.

Anatomy of Internal Heat Transfer

The magic happens within the MgO (Magnesium Oxide) insulation. In a high-quality heater, the NiCr 80/20 resistance wire is positioned as close to the sheath as possible.

The Physics: The thinner the MgO layer between the wire and the sheath, the faster the heat dissipates.

- High-Watt Density Heaters: The resistance wire (typically NiCr 80/20) is wound closely to the interior of the sheath, separated only by a thin layer of highly compressed MgO (Magnesium Oxide) powder. This proximity allows for rapid heat transfer and higher surface loads.

- Low-Watt Density Heaters: These often feature a “loose-fill” design where the heating coil is centered within the tube. While more economical, they cannot handle the extreme temperatures or vibration levels that high-density swaged versions can.

Core Component Breakdown

- Resistance Wire: NiCr 80/20 is the industry gold standard for its ability to withstand high temperatures without oxidizing.

- Insulation: High-purity MgO powder, vibration-compacted to provide maximum dielectric strength and thermal conductivity.

- Sheath Materials:

- SS304/316: Standard for most applications up to 650°C.

- Incoloy 800/840: Super-alloys designed for high-temperature oxidation resistance and corrosion resistance in demanding environments.

Cartridge vs. Tubular Heaters, What is the fundamental difference?

A cartridge heater is single-ended (wires exit one side), designed to be inserted into a hole. A tubular heater is typically double-ended and formed into specific shapes for air or liquid immersion. Cartridge heaters generally support significantly higher watt densities than standard tubular elements.

2. Technical Parameters and Tolerance Standards

Precision is the enemy of failure. In B2B procurement, “close enough” is never enough.

Diameter and Length Tolerances

To ensure a perfect fit in machined bores, high-quality heaters adhere to strict dimensional limits:

- Diameter Tolerance: Typically controlled within -0.02mm to -0.06mm. This ensures the heater is always slightly smaller than the nominal hole size to prevent seizing.

- Why? A standard 12mm hole is rarely exactly 12mm. If your heater is “true” 12mm, it won’t fit. If it’s 11.5mm, the 0.5mm air gap will act as a thermal barrier.

- The Result of Poor Fit: Heat cannot escape the heater. The internal temperature of the wire rises exponentially compared to the mold temperature, leading to a catastrophic “melt-out.”

- Length Tolerance: Generally ±1mm or ±2%, depending on total length.

Electrical Performance Metrics

- Insulation Resistance: ≥ 500MΩ at cold state.

- Leakage Current: ≤ mA at operating temperature.

- Power/Resistance Tolerance:

| Parameter | Standard Tolerance |

| Wattage | +5% / -10% |

| Resistance | +10% / -5% |

3. The Engineer’s 4-Step Selection Framework

Choosing the right heater is a thermodynamic calculation, not a guessing game.

Step 1: Determining “The Fit” (The Most Critical Step)

The gap between the heater and the mold is the #1 cause of failure.

- The Rule: The heater diameter should ideally be 0.05mm to 0.1mm smaller than the bore diameter.

- The Physics: Heat travels poorly through air. A gap larger than 0.15mm acts as an insulator, causing the internal wire to overheat and melt (burnout) while the mold remains cold.

Step 2: Calculating Total Wattage Requirement

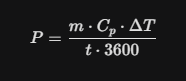

To find the power (P) required to heat a mass:

Where:

- m = Mass (kg)

- Cp = Specific Heat (J/kg*℃)

- △T = Temperature Rise (℃)

- t = Time (hours)

Step 3: Verifying Watt Density

Watt density is the amount of power per square inch/centimeter of the heated surface.

- Formula: Watt Density = Wattage/(π*diameter*heated length)

- Insight: High watt densities (above 20W/cm^2) require precision-fit holes and sophisticated PID control to survive.

Step 4: Sheath Material Selection

- Stainless Steel 304: Best for general-purpose heating (up to 650°C).

- Incoloy 800: Essential for high-temperature applications (up to 800°C) and environments where “cycling” (rapid on/off) is frequent.

Temperature isn’t the only factor; chemistry matters. Choosing the wrong sheath material is the leading cause of “pitting” and corrosion-based failure.

| Material | Max Sheath Temp | Best Used For… |

| SS304 | 650°C (1200°F) | General purpose, plastic molds, and low-temp dies. |

| SS316 | 650°C (1200°F) | Medical applications and mildly corrosive food processing. |

| Incoloy 800/840 | 800°C (1472°F) | High-temperature oxidation resistance; critical for heavy-cycling environments. |

The “Cold Zone” Requirement

Standard heaters include a 5-10mm Cold Zone at both ends. This is not a manufacturing flaw; it is a safety necessity. The cold zone ensures the lead wires do not oxidize at the terminal junction and allows the internal seal to remain intact.

4. Standard Metric & Imperial Specifications

For rapid replacement, refer to these common industry footprints:

| Nominal Diameter (Inch) | Metric Equiv. (mm) | Max Rec. Wattage (at 100mm length) |

| 1/4″ | 6.35 mm | 250W – 400W |

| 3/8″ | 9.53 mm | 400W – 700W |

| 1/2″ | 12.7 mm | 600W – 1200W |

| 5/8″ | 15.8 mm | 800W – 1800W |

| 3/4″ | 19.0 mm | 1200W – 2500W |

5. Installation & Maintenance: Preventing Premature Failure

Engineers don’t just replace parts; they solve problems. Here is how to diagnose your failed elements:

Lead Failure (Blackened Wires): The “Cold Zone” was inside the heated area, or the leads were exposed to temperatures above their rating (usually 250°C – 450°C).

Split Sheath (Bursting): Often caused by moisture. MgO is hygroscopic (it drinks water). If a heater sits in a humid warehouse, moisture enters. Upon power-up, it turns to steam instantly and bursts the tube. Solution: Pre-heat at 50% voltage if insulation resistance is ≤500 MΩ.

Seized Heater: The heater expanded and oxidized into the hole. Solution: Use a through-hole design or high-temp anti-seize lubricant during installation.

Even the best heater will fail if installed incorrectly.

The “Silent Killers” of Cartridge Heaters:

- Contamination: Oil, lubricants, or moisture in the bore can carbonize at high temperatures, creating a short circuit or “arc-over” at the lead end.

- Over-Extended Leads: Ensure the “Cold Zone” (unheated section) is positioned where the leads exit the hole. Leads should never be inside the heated bore.

- Lead Fatigue: If the heater moves (e.g., in a moving platen), use high-flexibility silicone or stainless steel braided leads to prevent breakage.

Troubleshooting:Why do my heaters keep burning out at the lead exit?

This is usually due to “wicking.” If the terminal end is not properly sealed or if the cold zone is too short, heat travels up the wires, degrading the insulation and causing a short. Ensure a minimum 10mm cold zone at the lead end.

6. Blue Ocean Opportunities: The Future of Cartridge Heating

For engineers looking for a competitive edge, the following “Blue Ocean” niches represent the next frontier of the industry:

- Micro-Cartridge Heaters (Dia < 3mm): As medical devices and semiconductors shrink, the demand for ultra-small, high-precision heating is exploding.

- Smart Heaters with Integrated Sensors: Eliminating external thermocouples by embedding Type K or J sensors directly inside the heater core for real-time, pinpoint thermal management.

- Harsh Environment Coatings: Specialized Teflon or ceramic coatings for heaters used in corrosive chemical processing where standard Incoloy fails.

7. Procurement Checklist (The Quick Quote Guide)

When requesting a quote from ht-heater.com, have these five data points ready to ensure a 100% technical match:

- Diameter: (Actual vs. Nominal)

- Overall Sheath Length: (Including Cold Zone requirements)

- Voltage & Wattage: (e.g., 240V, 500W)

- Lead Wire Type: (Fiberglass, Teflon, or Stainless Steel Braid)

- Application Environment: (e.g., Die casting, food processing, or vacuum)

Would you like our engineering team to review your current thermal profile?

[Contact an ht-heater.com Technical Specialist Today for a Free Selection Audit]