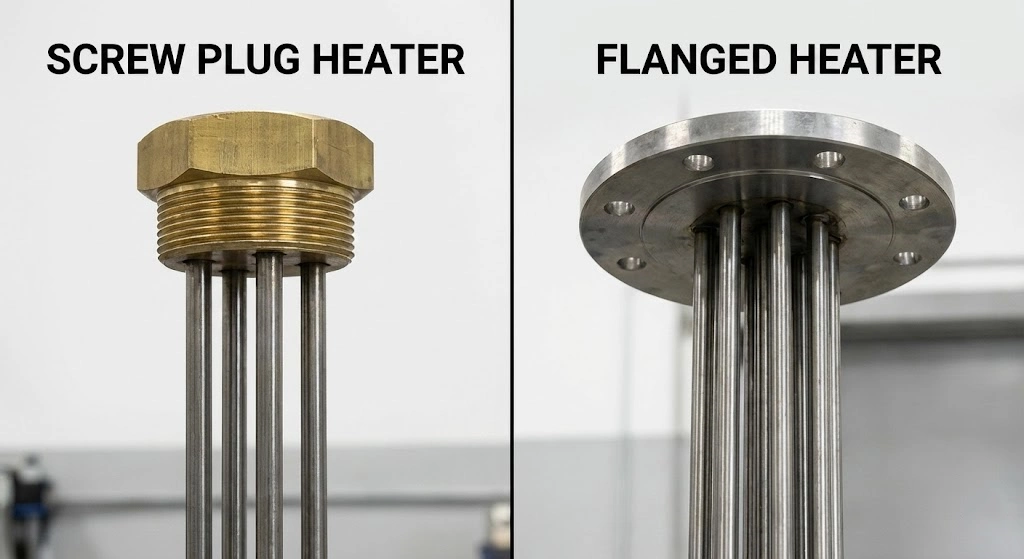

The Interface Constraints: What Fits Your Tank?

Selecting a heater usually starts with a constraint: the hole in the tank. If the vessel already has a 2-inch coupling welded on, ordering a 150# flange won’t work. Mechanical designers and process engineers need to look at two primary factors: the physical interface (Screw Plug vs. Flanged) 1 and the chemical compatibility of the fluid.

This guide breaks down the ASME and NPT standards to help you spec the right hardware for the job.

The Structural Face-Off: Screw Plug vs. Flanged

Pressure ratings and kilowatt requirements dictate the form factor. You need to know when to thread it in and when to bolt it down.

Screw Plug: The Compact Solution

For small to medium-sized water tanks, oil crankcases, or rinse tanks, the screw plug is the industry standard. These units screw directly into a threaded hex coupling welded to the tank wall.

- Standards: We manufacture these to standard National Pipe Thread (NPT) or BSP specifications, typically in 1″, 1.5″, 2″, and 2.5″ sizes.

- Limits: The hex head design is perfect for low-to-medium pressure applications where the heating element bundle is relatively small.

Flanged: Big Power, High Pressure

When the application demands kilowatts in the hundreds or the vessel is an ASME-coded pressure tank, screw threads aren’t enough. Flanged immersion heaters are the heavy artillery.

- Applications: These are mandatory for large storage tanks and high-pressure circulation heaters 2 heating flowing mediums.

- Standards: We adhere to ANSI flange standards ranging from 3″ up to 14″, typically in 150# or 300# pressure classes.

- Capacity: The larger surface area of the flange face allows us to weld in significantly more U-bent elements, creating massive heat transfer capability in a single penetration.

Material-Fluid Compatibility: The Cheat Sheet

Corrosion is the enemy. A heater that lasts ten years in oil might last ten days in acid. Use this material logic based on Hongtai’s manufacturing data.

Potable Water & Clean Water

Copper is the go-to material here3. It offers excellent thermal conductivity and resists corrosion in standard neutral water.

- The Ceiling: Copper has a thermal limit. Do not use it if the operating temperature exceeds 150°C4.

Thermal Fluid & Lubricating Oil

Steel is the rigid standard for oil immersion5. Oil doesn’t rust steel like water does.

- Thermal Limit: Steel sheaths handle up to 400°C6.

- Engineering Note: While the material can handle the heat, the oil might not. You must watch the Watt Density to prevent coking (See our Watt Density Calculation Guide).

Corrosive Liquids & Food Processing

Stainless Steel 304 is the baseline for “Corrosive liquids and food processing”7. It handles mild acids and meets sanitation requirements.

- The Upgrade Path: For harsher chemistries or higher temperatures, specify Stainless Steel 316 8or the superalloy Incoloy 800 9 to prevent stress corrosion cracking.

Liquid Level Management: Designing Against Dry Fire

Heaters are designed to transfer heat to liquid. If the liquid level drops and exposes the active element to air, it will fail in seconds.

Vertical Cold Zones

The solution is inside the tube. We utilize an integral cold pin technology10. By extending the internal non-heated pin, we push the active heating zone down.

- Design Tip: If you are installing a heater vertically from the top of a tank, calculate your lowest possible liquid level. The unheated “Cold Zone” must extend below this low-level mark to ensure the heated section is always submerged.

L-Shaped / Over-the-Side

For open tanks where cutting a hole isn’t an option, “Over-the-Side” heaters drop in from the top. The riser (vertical part) is unheated, and the elements concentrate the heat at the bottom of the tank.

[Image Text Description: Tank Cross-section diagram. Shows a tank with a “Min Liquid Level” line. The heater’s “Heated Length” is fully submerged below this line. The “Cold Zone” extends through the air gap and liquid surface.]

Electrical Connection & Protection

A water tank environment is inherently humid. Steam and condensation are constantly trying to bridge the electrical terminals.

Terminal Insulation

Plastic connectors often melt or track in high-heat environments. We utilize threaded screw terminals with ceramic or mica insulators11.

- The Benefit: These materials provide a “positive connection” 12 that resists vibration and prevents arcing (creepage) between terminals, even when the terminal box gets hot or damp.

Quick Reference: Screw Plug vs. Flanged

| Feature | Screw Plug Heater | Flanged Heater |

| Typical Interface | NPT / BSP Thread (1″ – 2.5″) | ANSI / DIN Flange (3″ – 14″) |

| Pressure Rating | Low to Medium | High Pressure (150# – 600#) |

| Power Capacity | Low to Medium (< 20kW) | High Capacity (> 20kW to MW) |

| Ideal For | Small tanks, crankcases, retrofits | Large storage tanks, boilers |

Below is the FAQ section in plain text format for your CMS:

Frequently Asked Questions (FAQ)

Q: Should I choose Copper or Stainless Steel for water heating?

If you are heating clean municipal water and temperatures remain below 150°C, Copper is the superior choice due to its high thermal conductivity and cost-effectiveness. However, for Deionized (DI) water, potable water with strict purity standards, or water with chemical additives, Stainless Steel 304 is recommended. Copper can leach ions into DI water or suffer corrosion from aggressive additives.

Q: Why can’t I use a water heater to heat oil?

Oil has much lower thermal conductivity than water. A heater designed for water typically runs at a high Watt Density (approx. 8-10 W/cm²). If you put this high-powered element into thick oil, the heat cannot escape fast enough. This causes the oil to carbonize (coke) onto the sheath, insulating the heater and causing it to burn out. Oil heaters always use Steel sheaths and are engineered with a much lower surface load (2-3 W/cm²).