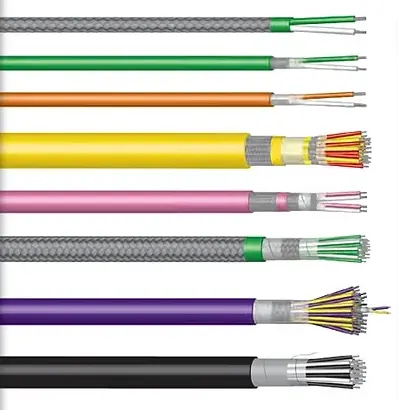

Thermocouple Extension Wire & Compensating Cable (Shielded)

Connecting a sensor to a PLC requires more than just copper wire. To maintain accuracy, you must use Thermocouple extension wire that matches the calibration of your probe. Hongtai manufactures a full range of Extension (Grade X) and Compensating (Grade C) cables designed to carry the millivolt signal faithfully over long distances.

In modern factories, electrical noise from VFDs (Variable Frequency Drives) and motors can destroy measurement accuracy. Our Shielded instrument cable features a stainless steel overbraid or aluminum foil shield with a drain wire. This “Faraday Cage” blocks electromagnetic interference (EMI), ensuring stable, jitter-free temperature readings.

Key Technical Features & Benefits

-

Matched Accuracy:

-

Extension Grade (X): Uses the same alloy as the thermocouple. Higher accuracy.

-

Compensating Grade (C): Uses cheaper alloys with similar output characteristics. Cost-effective for Type S/R/B.

-

-

Interference Free: Options for Stainless Steel Metal Braid (SSB) or Mylar Foil Shielding to prevent signal noise in noisy electrical cabinets.

-

Insulation Options:

-

PVC: Economical, waterproof (105°C). General use.

-

Teflon (FEP/PFA): Chemical resistant, non-stick, high temp (200°C/260°C).

-

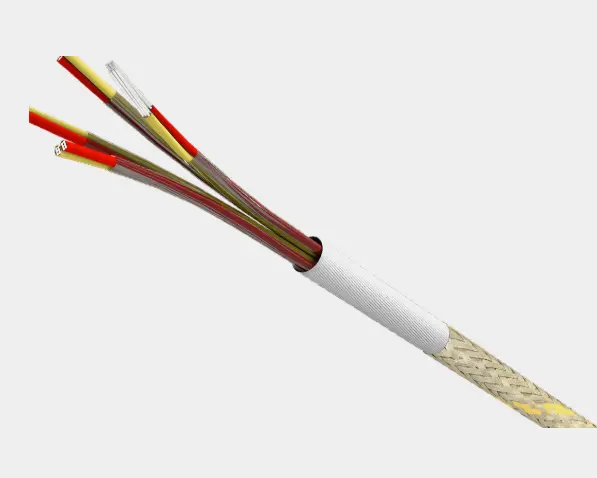

Fiberglass: For hot zones and ovens (400°C – 600°C).

-

-

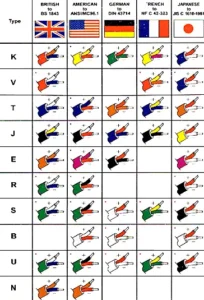

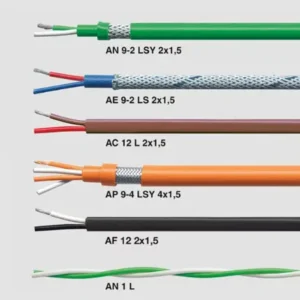

Color Coded: Jackets conform to ANSI/IEC/JIS color standards for easy identification.

Technical Specifications

| Parameter | Extension Grade (KX, JX, EX) | Compensating Grade (KC, SC, BC) |

| Conductor Material | Same as Thermocouple (e.g., NiCr-NiAl) | Copper Alloys (e.g., Cu-CuNi) |

| Accuracy | Standard: ±1.5°C / Precision: ±1.1°C | Standard: ±2.5°C |

| Insulation | High temp fiberglass wire, PTFE, PVC, Silicone | PVC is most common |

| Shielding | SS Wire Braid (SSB) / Al-Foil | Tinned Copper Braid |

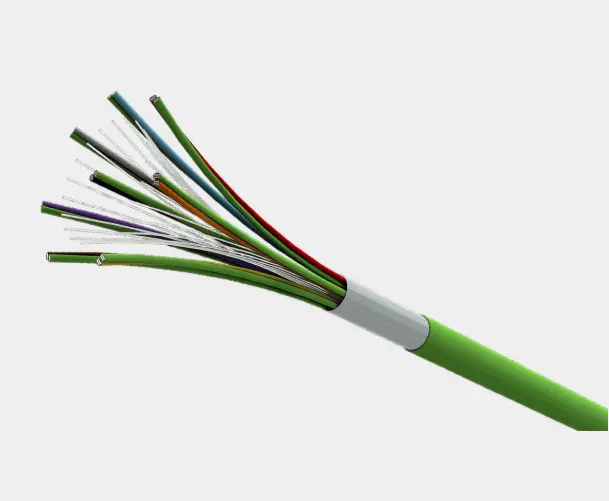

| Core Structure | Solid or Stranded (Flexible) | Stranded (7/0.2mm, 7/0.3mm) |

| Temp Range | -60°C to +400°C (Fiberglass) | -20°C to +105°C (PVC) |

Wire Selection Guide

-

For High Heat (Ovens/Kilns): Choose Fiberglass insulation with SS Braid. PVC will melt.

-

For Chemical Tanks: Choose Teflon (PFA) insulation. It resists acid and moisture.

-

For Long Runs (Cost Saving): Use Compensating cable (Type KC/SC) for Type S/R thermocouples. Running pure Platinum wire 100 meters is too expensive; compensating cable saves 90% of the cost.

Application Scenarios

-

System Integration: Wiring control cabinets to field sensors.

-

Heat Treating: Connecting load thermocouples to chart recorders.

-

Automotive Testing: Type K thermocouple wire used for EGT and brake testing harnesses.

-

Plastics: Drag-chain compatible cables for moving injection molding carriages.

FAQ

Q: Can I use copper wire to extend a thermocouple?

A: No. Using copper wire creates two new “cold junctions” at the connection point. This will introduce an error equal to the temperature difference between the connection point and the instrument (often 20°C-50°C error). You must use matching extension wire.

Q: What is the difference between Solid and Stranded wire?

A:

-

Solid: Better for fixed installation (conduit). Easy to terminate.

-

Stranded: Better for flexible applications (handheld probes). Resistant to vibration breakage.

Connect these cables with our Thermocouple Connectors.

Read about Shielding and Grounding Techniques.