In the industrial manufacturing sector, thermal inefficiency is a silent profit killer. A heater failure doesn’t just cost the price of a replacement part; it costs hours of production downtime. For engineers and procurement managers, the challenge in 2026 isn’t just buying a heater—it’s specifying a thermal solution that matches the exact hydrodynamic and thermodynamic […]

Read MoreHeating Solutions: Expertise You Can Trust

Gain valuable insights and practical knowledge from our 30 years of heating industry experience.

Incoloy 800 vs. 304 Stainless Steel: A Thermal & Corrosion Performance Comparison for Heating Sheaths

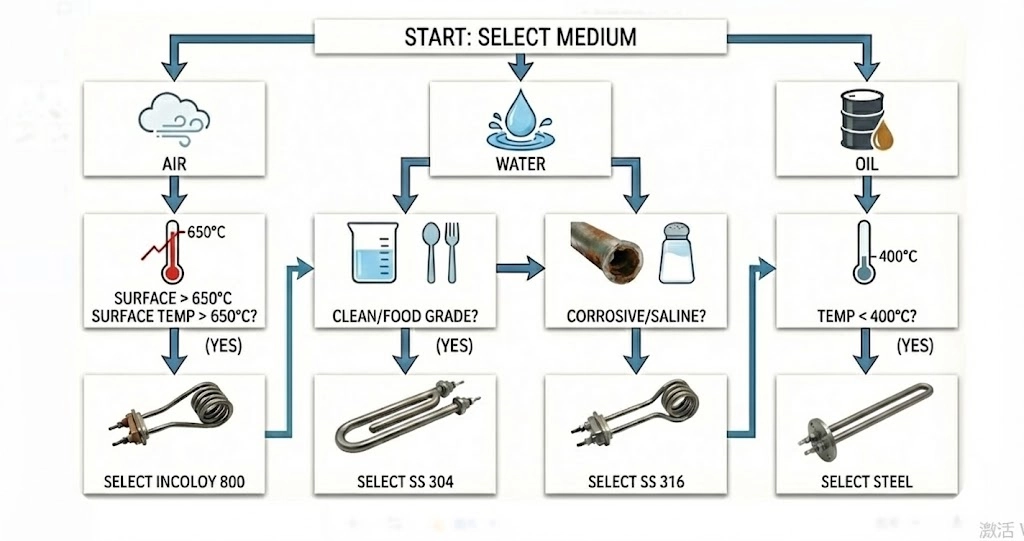

The Engineering Context: It’s Not the Wire, It’s the Sheath When selecting heating elements for industrial applications, the choice often comes down to Incoloy 800 vs 304 Stainless Steel. Understanding the differences in corrosion resistance, temperature limits, and cost is crucial for your project’s success. In industrial heating element failure analysis, a staggering 60% of […]

Read MoreCalculating Watt Density for Tubular Heaters: Formulas, Max Thresholds & Tolerance Correction

1. The Physics of Failure: Why Surface Load Matters In thermal system design, the total wattage defines the energy input, but the Watt Density (Surface Load) defines the heater’s lifespan. Watt Density, expressed in Watts per Square Inch (W/in^2) or Watts per Square Centimeter (W/cm^2), represents the rate at which thermal energy is transferred from […]

Read MoreForensic Analysis of Tubular Heater Failure: 5 Common Root Causes & Prevention Strategies

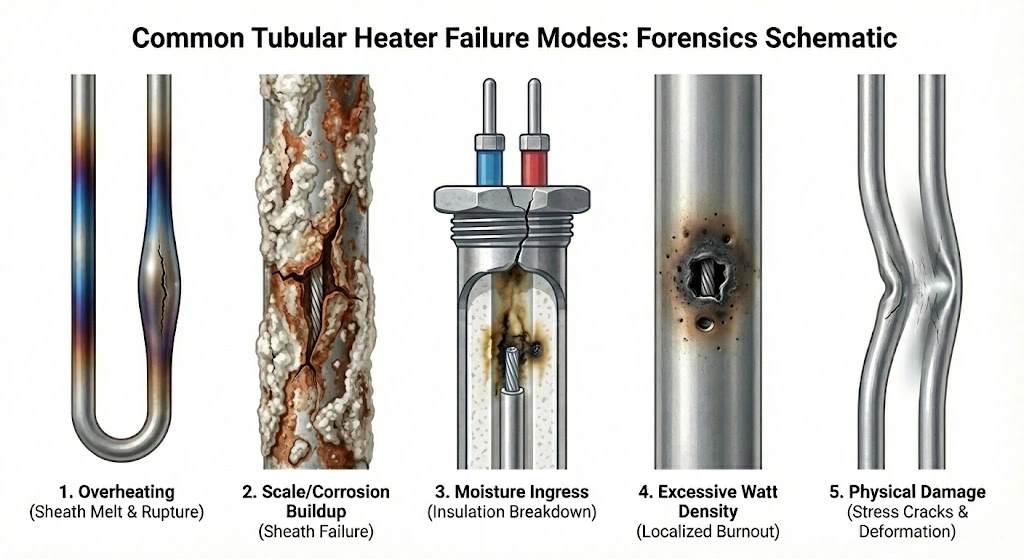

The Cost of Failure: Beyond the Component Price In industrial maintenance, the cost of a failed tubular heater is rarely the $50 replacement part. It is the $5,000 per hour in downtime, the wasted batch of raw materials, and the disruption to the production schedule. Most heater failures are dismissed as “wear and tear.” However, […]

Read MoreDesigning Finned Tubular Heaters for Forced Air: Balancing Heat Transfer, Pressure Drop & Velocity

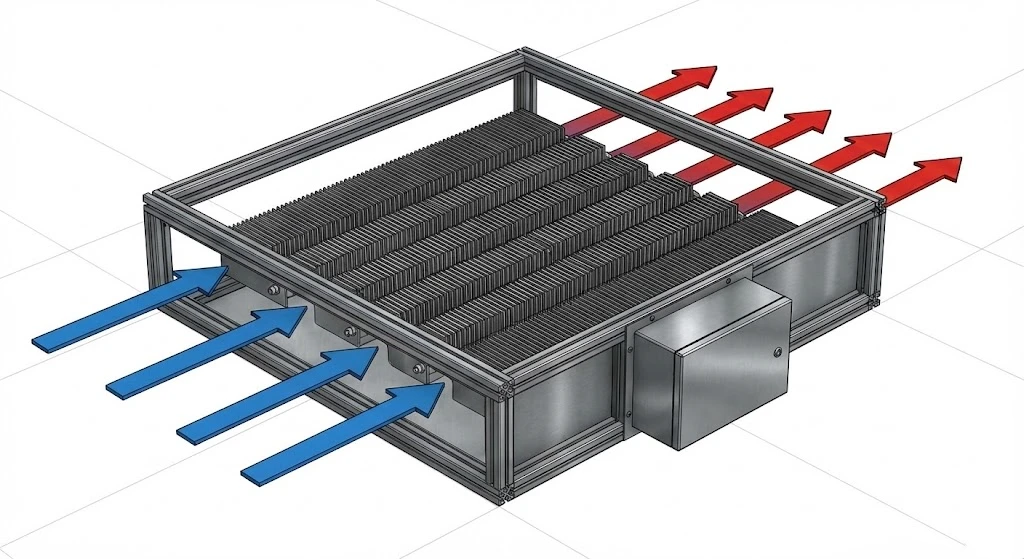

The Conductivity Challenge: Why Air is Difficult to Heat For thermal engineers, air is a notoriously difficult medium. Its thermal conductivity is approximately $0.026 W/m\cdot K$—roughly 20 times lower than stationary water. If you place a standard “bare” tubular heater in an air stream, the heat cannot escape the sheath fast enough. The result? The […]

Read MoreWhy French Manufacturers Swear By Hongtai’s Band Heaters: A 2025 Shipment Deep Dive

In the competitive European market, sourcing high-quality industrial band heaters is a challenge for many French manufacturers.October 2025 – Hongtai just wrapped up a critical shipment of 2,400+ band heaters to France, supplying clients from Île-de-France’s auto parts plants to Auvergne-Rhône-Alpes’s plastic injection shops and Provence-Alpes-Côte d’Azur’s food processing sites. These aren’t your run-of-the-mill off-the-shelf […]

Read More2026 Cartridge Heater Ultimate Guide: From Selection Logic to Failure Analysis

Introduction In industrial thermal processing, a cartridge heater is often viewed as a simple commodity. However, for the maintenance manager facing a line shutdown or the R&D engineer designing a high-speed packaging die, these components are anything but simple. Premature burnout, uneven heating, and seized elements are rarely “bad luck”—they are usually the result of […]

Read MoreIndustrial Immersion Heaters: Screw Plug vs. Flanged Selection, Port Standards & Fluid Dynamics

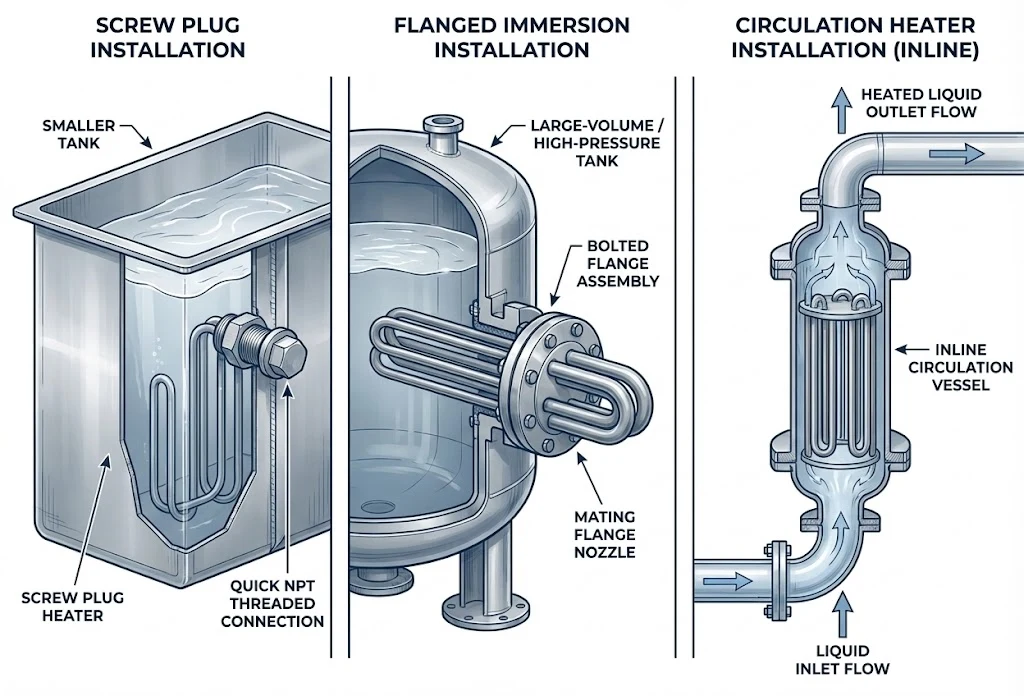

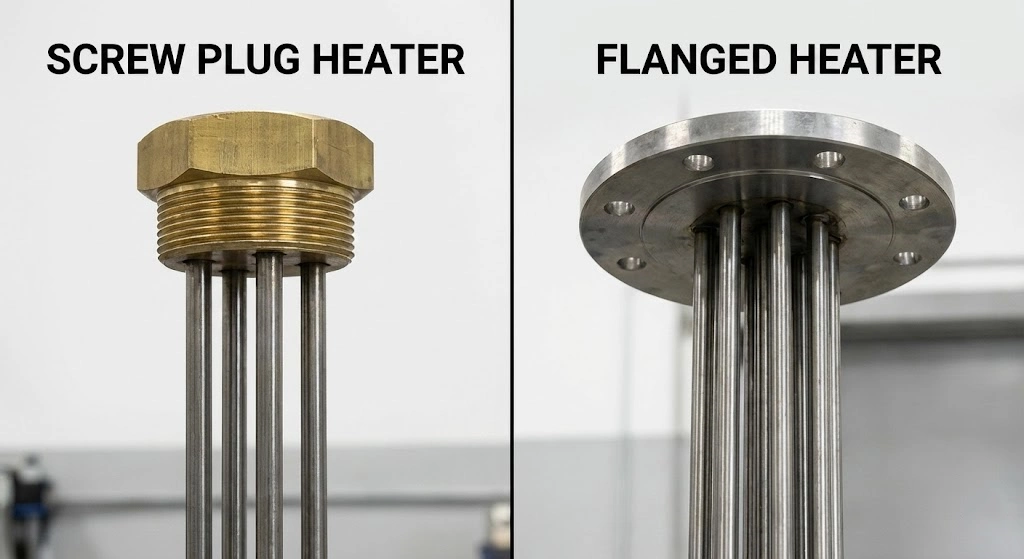

The Interface Constraints: What Fits Your Tank? Selecting a heater usually starts with a constraint: the hole in the tank. If the vessel already has a 2-inch coupling welded on, ordering a 150# flange won’t work. Mechanical designers and process engineers need to look at two primary factors: the physical interface (Screw Plug vs. Flanged) […]

Read MoreCartridge Heater Temperature Control: The Ultimate Guide to Thermocouples, PID & SSRs

Introduction A high-density cartridge heater without a control system is not a tool; it is a fuse waiting to blow. In high-watt density applications, the internal temperature of a heater can rise at a rate of 50°C per second. If you rely on a manual switch or a slow-reacting external sensor, the heater core will […]

Read MoreLow Insulation Resistance? Don’t Scrap It! The “Bake Out” Guide to Reviving Wet Industrial Heaters

The “Monday Morning” Panic It’s a classic scenario. You took out a batch of heating tubes that had been in the warehouse for several months. Your quality control team pulls one out, hooks up a Megohmmeter (Megger), and sees a reading of 0.5 MΩ. The immediate reaction? “Defective product. Return it.” Stop. Put down the […]

Read MoreThe Cartridge Heater “Autopsy”: Diagnosing Failures and Doubling MTBF

Introduction A production line stops. You pull out a cartridge heater and find it blackened, swollen, or with leads melted into a sticky mess. Most maintenance teams simply swap it for a new one, only to face the same failure two weeks later. At ht-heater.com, we believe a failed heater is a “witness” that tells […]

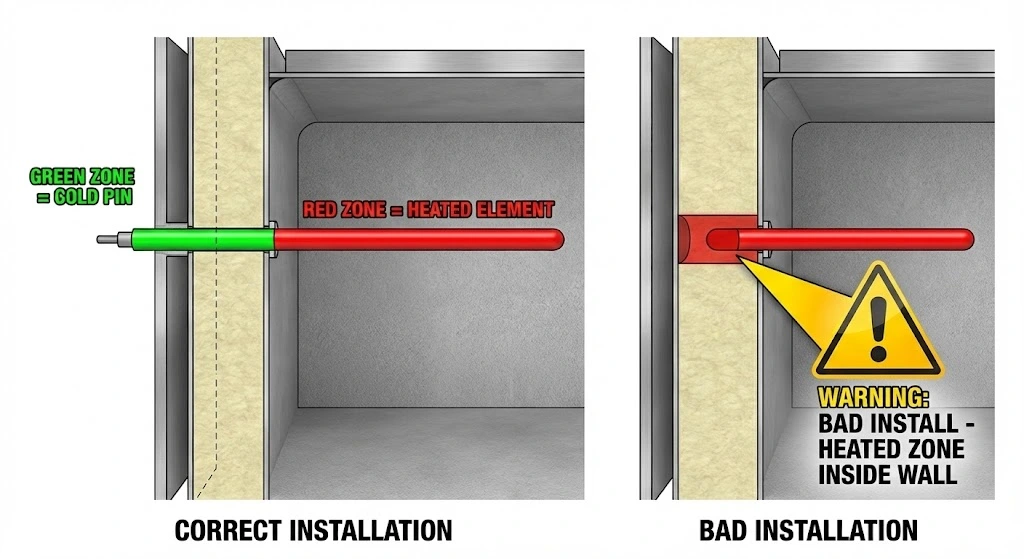

Read MoreTubular Heater Installation & Wiring Guide: Torque Specs, Cold Pin Alignment & Terminal Protection

The Weakest Link: It’s Not the Element, It’s the Connection Correct tubular heater installation is vital for preventing premature failure and ensuring electrical safety. The tubular heating element itself is built like a tank—compressed MgO and heavy-gauge alloys. But the connection point? That is the Achilles’ heel. In the field, 9 out of 10 “heater […]

Read More