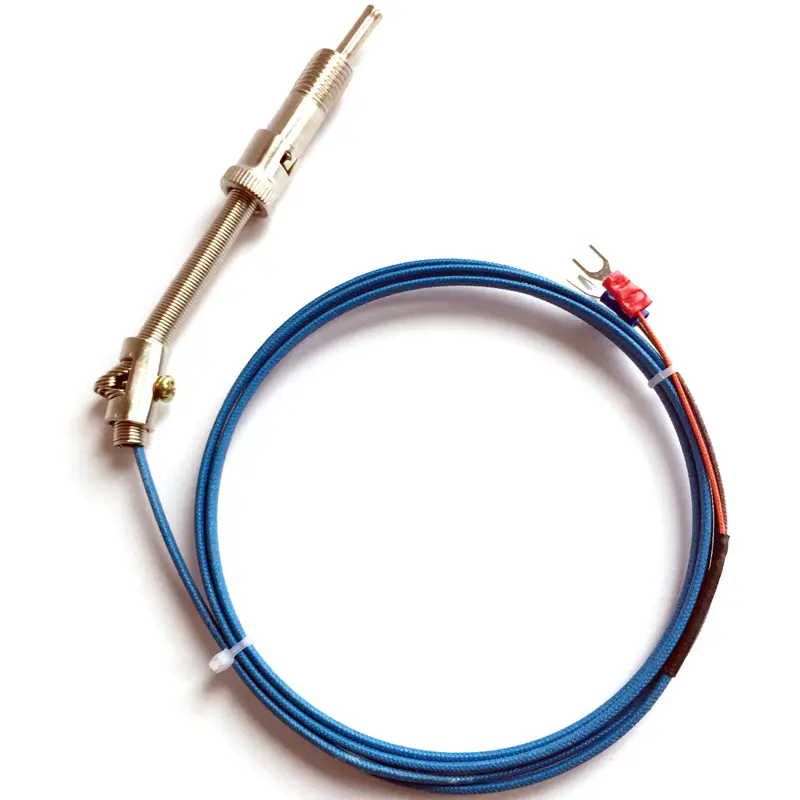

Teflon Coated Thermocouple (PFA) for Acid Baths

In the aggressive world of chemical processing and surface finishing, metal sensors corrode in days. The Hongtai Teflon Coated Thermocouple is the industry standard for immersion in strong acids, alkalines, and anodizing solutions.

Unlike standard stainless steel probes, this Acid resistant temperature sensor is completely encapsulated in a seamless layer of PFA (Perfluoroalkoxy) or FEP fluoropolymer. This coating provides an impenetrable barrier against Sulfuric Acid, Hydrochloric Acid, and caustic soda, making it the ideal Electroplating temperature sensor for ensuring plating quality without contaminating the bath.

Key Technical Features & Benefits

-

Seamless Coating Technology: We use a proprietary extrusion process to coat the stainless steel probe and the transition cable in a continuous layer of PFA. This means there are no joints or seams where liquid can penetrate.

-

Total Corrosion Resistance: PFA/PTFE is inert to almost all industrial chemicals. It can withstand pH 0-14 environments without pitting or degrading.

-

Waterproof & Submersible: Designed as a Chemical bath probe, the entire assembly (probe + cable) can be submerged directly into the tank.

-

Non-Stick Surface: The low surface energy of Teflon prevents chemical buildup and crystallization on the sensor, ensuring fast response times and easy cleaning.

-

Electrical Isolation: The coating acts as an electrical insulator, preventing short circuits in electrolysis tanks (e.g., Anodizing or Chrome Plating).

Technical Specifications (WRF-Corrosion Series)

| Parameter | Specification | Material Detail |

| Product Type | Teflon coated thermocouple | Flexible Cable Type / Rigid Rod |

| Coating Material | PFA (Standard), FEP, PTFE | PFA offers best durability |

| Calibration | Type K, Type J, PT100 (RTD) | Type K is most common |

| Temp Range | -200°C to +250°C | Limited by coating melting point |

| Probe Core | Stainless Steel 316L (Inner) | Provides rigidity |

| Cable Length | 2m, 3m, 5m, 10m | Fully coated length |

| Diameter | 4mm, 5mm, 6mm (Coated OD) | – |

| Mounting | Flange (PTFE) or Compression Fitting | Plastic fittings recommended |

Industry Applications

-

Electroplating & Anodizing: Monitoring chrome, nickel, and gold plating baths where temperature affects coating thickness and brightness.

-

Chemical Manufacturing: Pickling tanks (HCL/H2SO4) and storage of corrosive liquids.

-

Semiconductor: Etching baths requiring ultra-high purity sensors (PFA does not leach contaminants).

-

Fertilizer Plants: Processing acidic phosphate solutions.

PFA vs. PTFE: What’s the difference?

While often called a PTFE coated sensor, we primarily use PFA for the outer jacket.

-

PTFE (White): Excellent chemically, but microporous. Over time, acid vapor can penetrate it.

-

PFA (Clear/Translucent): Melt-processable with lower porosity. It forms a tighter, non-porous seal on the metal core, offering superior long-term leak protection in hot acids.

FAQ

Q: Can I use this in Chromic Acid?

A: Yes. PFA is fully resistant to Chromic Acid used in hard chrome plating.

Q: What happens if I scratch the coating?

A: The coating is the only barrier. If the PFA layer is cut or scratched deeply, the acid will attack the inner metal core, and the sensor will fail. Handle with care during installation. Do not let the probe touch the tank heaters.

Q: Can it measure above 300°C?

A: No. Fluoropolymers melt around 260°C – 300°C. For corrosive applications above 300°C, you must use our Ceramic or Tantalum sheath thermocouples.

Pair with our Corrosion Resistant Immersion Heater for a complete tank solution.