1. Industrial Oven Heating Elements (Convection & Baking)

Hongtai manufactures high-performance industrial oven heating elements engineered for the rigorous thermal demands of commercial food production, powder coating, and heat-treating furnaces. Unlike standard residential parts, our elements are built with heavy-wall Incoloy 800 or Stainless Steel 304 sheaths to withstand continuous high-temperature cycling (up to 800°C) and corrosive oven atmospheres.

We specialize in OEM solutions for oven manufacturers, offering precision-formed tubular heaters (W-Shape, M-Shape, or Planar Coils) designed to maximize heat transfer area and ensure uniform airflow distribution.

Key Technical Features:

-

Core Technology: High-purity Magnesium Oxide (MgO) compaction for maximum dielectric strength.

-

Sheath Materials: Incoloy 800 (Recommended for High-Temp), SS304, SS321.

-

Max Temperature: 800°C (1472°F) for Incoloy models.

-

Formability: 1050°C Bright Annealed sheath allows for complex 3D bending without cracking.

-

Voltage: 208V, 240V, 480V, 600V (Single or 3-Phase).

-

Watt Density: Optimized watt density design to prevent element burnout in still-air or forced-convection ovens.

2. Technical Specifications & Dimensions

The following specifications cover our standard production capabilities for commercial baking elements and industrial air heaters. We can reverse-engineer discontinued elements for maintenance distributors or design custom heaters for new oven lines.

| Parameter | Standard Specification | Customizable Options |

| Sheath Diameter | 6.5mm, 8.0mm, 8.5mm, 10mm | 12mm, 14mm, 16mm, 20mm |

| Sheath Material | Stainless Steel 304 | Incoloy 800, SS321, SS310S |

| Max Length (Straight) | 3000mm | Up to 7000mm (Diameter dependent) |

| Voltage | 240V / 480V | 120V – 600V |

| Wattage Tolerance | +5% / -10% | Precision tolerance available |

| Cold Zone Length | Standard 50mm – 100mm | Custom based on wall insulation thickness |

| Terminal Types | Threaded Stud (#10-32, M4, M5) | Quick Connect (Spade), Ceramic Block |

Standard Forming Configurations

Figure : Common Oven Heater Shapes.

W-Shape (M-Bend): The standard for rectangular oven cavities, providing uniform coverage.

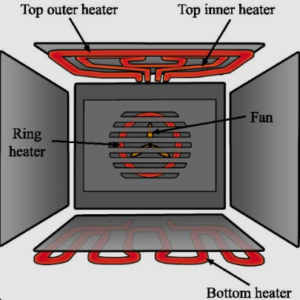

Double-Loop / Racket: Common in convection ovens to encircle the fan assembly.

Planar Coil: Used for radiant heating applications.

3. Advanced Manufacturing & Sheath Treatments

To ensure longevity in industrial environments, Hongtai employs advanced metal treatment processes that distinguish our oven heating elements from standard replacements.

High-Temperature Bright Annealing (1050°C)

For elements requiring complex geometries (such as tight “W” bends or multi-loop convection coils), we perform Bright Annealing at 1050°C.

-

Benefit: This restores the ductility of the stainless steel or Incoloy sheath after the rolling/compaction process. It eliminates internal mechanical stress, preventing the sheath from cracking during the bending process or during thermal expansion in the oven.

Surface Treatment: Green Passivation & Blackening

We offer specialized surface treatments to enhance performance:

-

Green Passivation: Creates a robust protective oxide layer that resists corrosion from humidity or chemical vapors released during baking/curing processes.

-

Blackening (Black Annealing): A process that turns the sheath surface black.

-

Why use it? A black surface has higher emissivity than shiny metal. This allows the element to radiate heat more efficiently into the oven chamber, reducing the internal temperature of the wire and extending the element’s life.

-

Installation & Wiring Guide

-

Airflow: In forced-convection ovens, align the element loops perpendicular to the airflow for maximum heat transfer.

-

Insulation: Ensure the ceramic insulators on the terminals are positioned outside the oven’s insulation wall to keep the electrical connections cool (below 200°C).

4. Frequently Asked Questions

Q: Can you manufacture replacement bake elements for specific commercial brands (e.g., Blodgett, Hobart, Vulcan)?

A: Yes. As an OEM manufacturer, we can replicate oven heating elements for any major commercial brand. Simply provide the voltage, wattage, and physical dimensions (or a sample), and we can manufacture a functional equivalent with upgraded materials (e.g., Incoloy 800) for longer life.

Q: What is the lead time for custom W-shape oven elements?

A: For custom bent elements, our typical lead time is 7-10 working days. We understand the cost of downtime in industrial baking, so we offer expedited production for urgent maintenance orders.

Q: Why do my oven elements keep failing?

A: Premature failure is often caused by excessive watt density (too much power in too small a space) or insufficient airflow. If you are experiencing frequent burnouts, our engineering team can redesign the element with a larger diameter or longer length to lower the watt density while maintaining the same total heating power.

Don’t know how to choose? You can check here:The 2026 Engineering Guide to Tubular Heaters: Selection, Customization, and Efficiency or contact us directly.