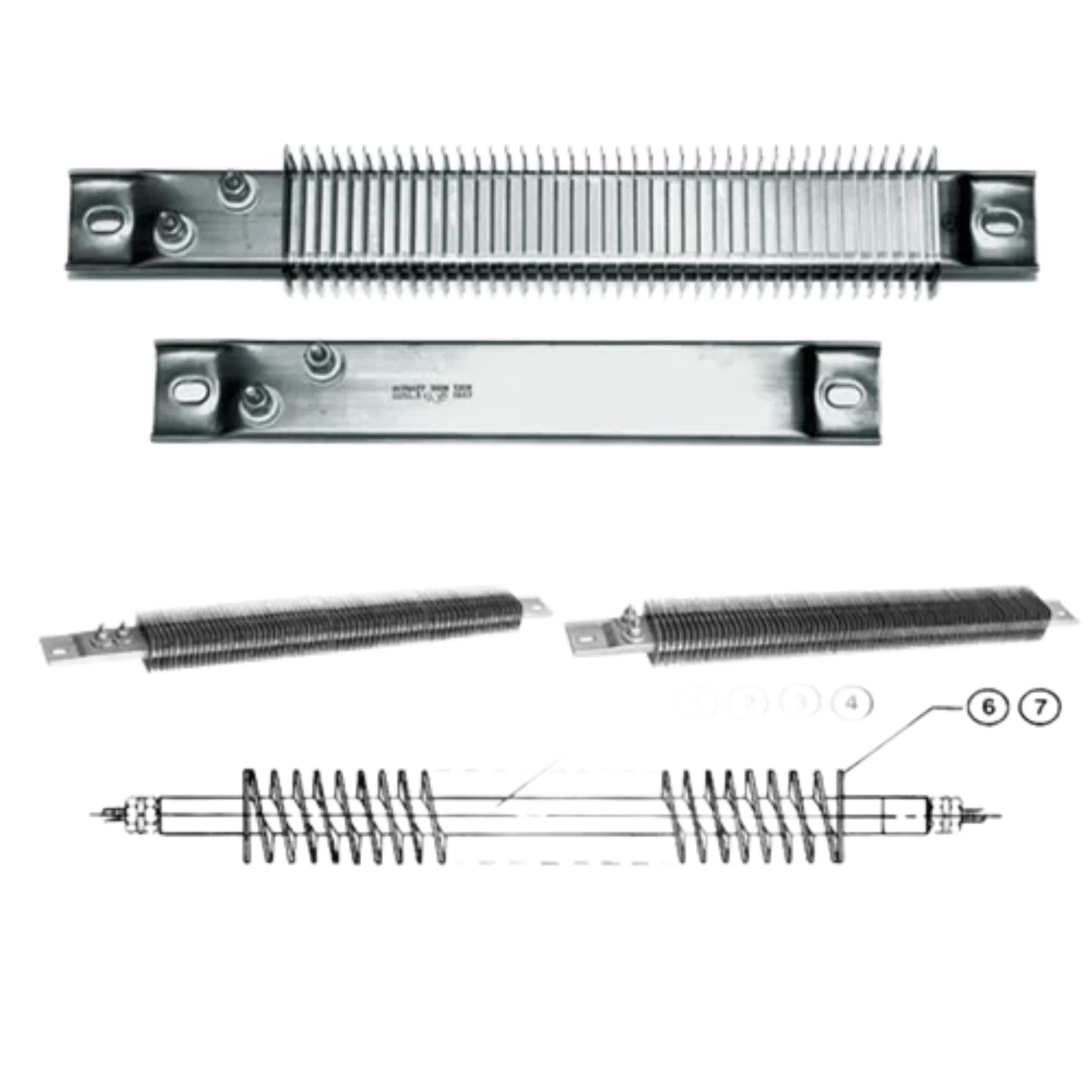

Core Value: The Aluminum Strip Heater 300mm with Cooling Fins is engineered for maximum heat dissipation in forced air or natural convection heating applications. By integrating high-grade aluminum cooling fins, the surface area is increased by 500% compared to standard strip heaters, allowing for higher wattage capabilities without element overheating. This 300mm (approx. 12-inch) unit allows for rapid heat transfer to the air stream, making it ideal for load banks, duct heating, and moisture protection in control cabinets. BACKED BY 30+ YEARS MANUFACTURING EXPERIENCE and UNDERGOES MULTIPLE RIGOROUS QUALITY CHECKS for reliable industrial performance.

- ✓ Maximized Surface Area: Cooling fins increase heat transfer efficiency to air by 5x.

- ✓ Compact Power: High watt density capability in a compact 300mm footprint.

- ✓ Aluminum Fins: Superior thermal conductivity (205 W/mK) compared to steel fins.

- ✓ Rugged Construction: Vibration-resistant design suitable for industrial machinery.

- ✓ Corrosion Resistant: Aluminum fins and SS sheath withstand humid environments.

- ✓ Fast Response: Low thermal mass allows for quick heat-up and cool-down.

- ✓ Reliable Quality: 30+ YEARS MANUFACTURING EXPERIENCE ensures longevity.

- ✓ Quality Assured: UNDERGOES MULTIPLE RIGOROUS QUALITY CHECKS.

- ✓ Global Standards: CE, LVD, RoHS, ISO 9001 certified.

Technical Specifications & Performance Data

| Parameter | Standard Value | Customizable Range | Notes |

|---|---|---|---|

| Heater Length | 300mm (11.8 Inch) | 100mm – 2000mm | Standard modular size |

| Fin Material | Aluminum 6063 | Stainless Steel | High thermal conductivity |

| Fin Dimensions | 50mm x 35mm (Typical) | Custom Fin Sizes | Rectangular profile |

| Power Rating | 500W – 1000W | 100W – 2000W | Depends on airflow |

| Voltage Rating | 240V AC 1-phase | 120V / 480V | 50/60Hz compatible |

| Sheath Material | Stainless Steel 304 | Incoloy 800 | Heater core protection |

| Max Temperature | 300°C (Air Temp) | – | Requires airflow |

| Mounting | Offset Mounting Tabs | Through-holes | Easy installation |

| Air Velocity | Recommended > 3 m/s | Natural Convection | Higher flow = Higher Wattage |

| Termination | 10-32 Post Terminals | Leads / Ceramic Block | High-temp connection |

| Warranty | 1 Year Standard | Quality assured | COMPREHENSIVE QUALITY ASSURANCE |

Industrial Applications & Solutions

- Load Banks: Resistive load testing for generators and batteries. The aluminum fins allow for rapid heat dissipation, preventing the resistor elements from burning out during high-current testing.

- Control Cabinet Heating: Prevents condensation and freezing in outdoor electrical panels. The finned design provides gentle, uniform convection heat to keep electronics dry.

- Duct Heating (HVAC): Booster heating in air ducts. Low air resistance fins allow for efficient heat transfer to the passing air stream without significant pressure drop.

- Industrial Ovens: Convection drying and curing ovens. Ideal for applications requiring clean electric heat with forced air circulation.

- Shrink Tunnels: Air heating for shrink wrap packaging. Fast response time ensures consistent temperature control for varying conveyor speeds.

- Dehumidification Systems: Used in industrial dehumidifiers to heat regeneration air. Rugged fin construction withstands continuous cycling.

HT-Heater vs Standard Market Heaters

| Feature | HT-Heater (Factory) | Standard Market | Your Advantage |

|---|---|---|---|

| Fin Material | Aluminum (High Conductivity) | Steel (Low Conductivity) | Better heat transfer to air |

| Fin Attachment | Mechanically Bonded | Loosely Crimped | No rattling, consistent heat |

| Surface Area | Optimized Fin Pitch | Wide Spacing | Maximized heat dissipation |

| Sheath Quality | Seamless SS304 | Seamed Tube | Moisture resistance |

| Manufacturing Experience | 30+ YEARS EXPERIENCE | New factories | Proven design stability |

| Quality Assurance | MULTIPLE RIGOROUS QUALITY CHECKS | Batch check only | ZERO DEFECT DELIVERY |

Installation & Integration Guidelines

- Airflow Orientation: Install heaters so fins are parallel to the airflow direction. This minimizes air resistance and maximizes heat stripping.

- Spacing: Maintain at least 50mm spacing between heaters when banking them together. This prevents radiant heat overlap and ensures each unit operates efficiently.

- Wiring: Use high-temperature nickel-plated steel lugs. Standard copper lugs may oxidize at operating temperatures. Support lead wires to prevent stress on terminals.

- Mounting: Use the offset mounting tabs to allow for thermal expansion. Rigidly fixing both ends without expansion room can cause the heater to bow.

Customer Success Stories

Case 1: Load Bank Manufacturer (USA)

Application: 500kW portable load bank for generator testing.

Challenge: Previous steel-finned heaters were overheating and warping under full load.

Solution: 300mm Aluminum Finned Strip Heaters, 1000W each.

Results: HEAT DISSIPATION IMPROVED BY 40%. “The aluminum fins make a huge difference. HT-Heater UNDERGOES MULTIPLE RIGOROUS QUALITY CHECKS ensures they handle the amps.”

Case 2: Telecom Outdoor Cabinets (Sweden)

Application: Anti-condensation heating for 5G tower cabinets.

Challenge: Humidity causing short circuits in winter.

Solution: 300W Finned Heaters mounted at the cabinet base.

Results: ZERO MOISTURE FAILURES. “30+ YEARS MANUFACTURING EXPERIENCE shows. Reliable convection heating kept our equipment dry all winter.”

Case 3: Food Drying Oven (Thailand)

Application: Fruit dehydration tunnel.

Challenge: Need clean, electric heat with fast recovery after door opening.

Solution: Bank of 50 finned strip heaters with high-velocity fans.

Results: DRYING TIME REDUCED BY 15%. “The heat transfer is instant. Excellent quality.”

Pricing & Procurement Options

Standard Production: MOQ 10 pieces. BACKED BY 30+ YEARS MANUFACTURING EXPERIENCE ensures consistent quality. Discounts for 50+ units. Standard models in stock.

Lead Times: Standard: 7-10 days production. Custom: 10-15 days. Samples: 5-7 days. Rush service available for urgent requirements.

Global Logistics: Worldwide shipping via UPS, DHL, FedEx, EMS, TNT or the shipping agent as your request. Every shipment backed by 30+ YEARS MANUFACTURING EXPERIENCE.

Sample Orders: Samples are paid. Contact sales for sample pricing. All samples UNDERGO MULTIPLE RIGOROUS QUALITY CHECKS.

Global Certifications & Compliance

- CE Marking

Conforms to European directives - LVD Compliance

Electrical safety requirements - RoHS Compliant

Environmentally safe materials - ISO 9001

Rigorous quality control processes

Quality Documentation: Certificate of Conformity and resistance test reports available. Every unit UNDERGOES MULTIPLE RIGOROUS QUALITY CHECKS before shipment.

Comprehensive After-Sales Support

Warranty: 1 Year Standard Warranty against manufacturing defects.

Technical Support: Application engineering for airflow velocity calculation and watt density selection.

Service Network: BACKED BY 30+ YEARS MANUFACTURING EXPERIENCE. Global technical support available.

Ready for Efficient Air Heating?

Next Steps:

- 📧 Request Custom Quote – Specify length, watts, and volts

- 🔧 Free Application Review – Optimize your airflow heating

- 📦 Order Test Unit – Verify performance on your equipment

- 📞 Contact Heating Experts – Response within 2 hours

Leading Manufacturer & Export of Industrial Heaters

Providing A One Stop Solutions To All Industrial Heaters Needs

SINCE 1990 Professional Heater Producer | Our Products Undergo Multiple Rigorous Quality Checks